Balancing Machines

Turning Concepts into Reality

Our Products

Discover Our Balancing Machines

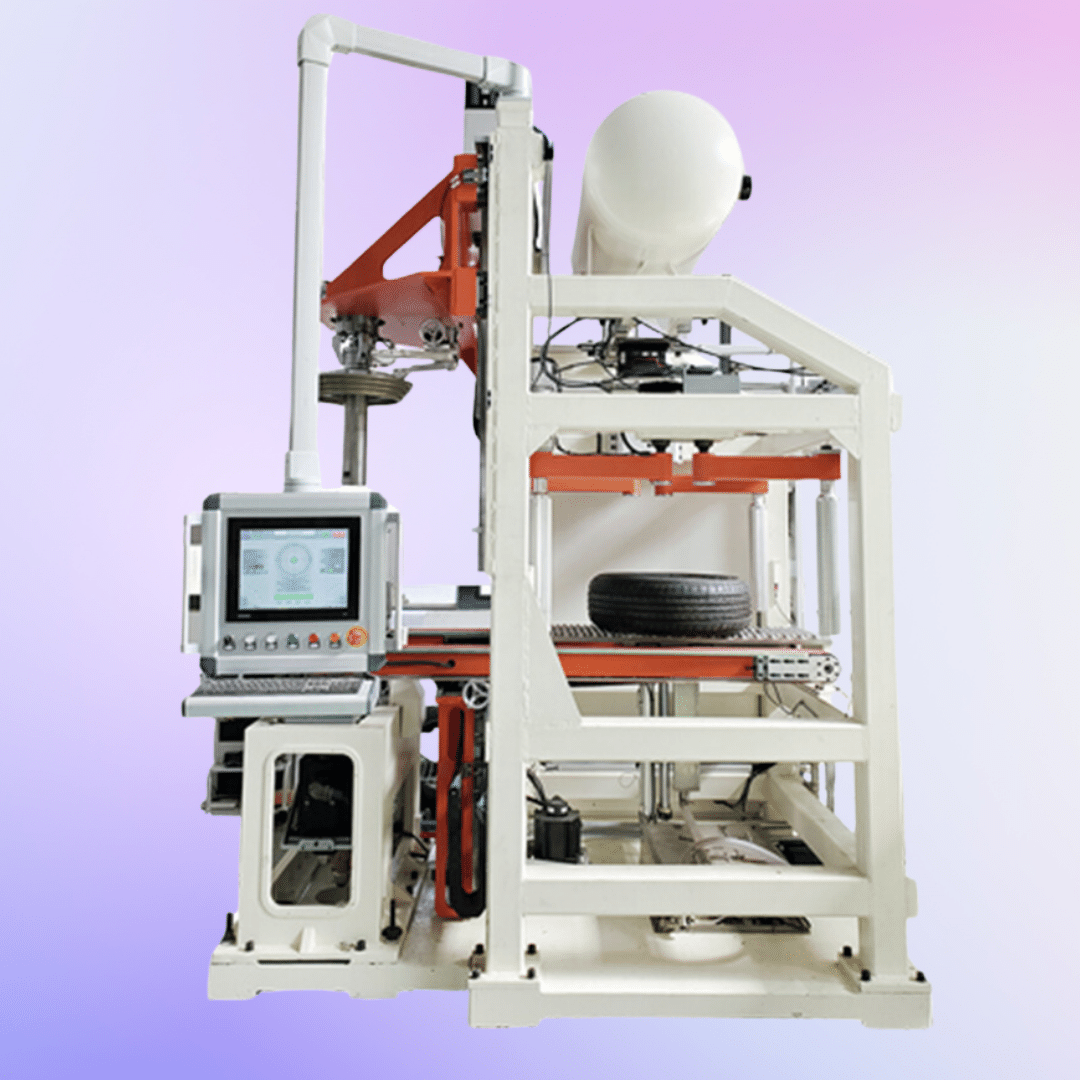

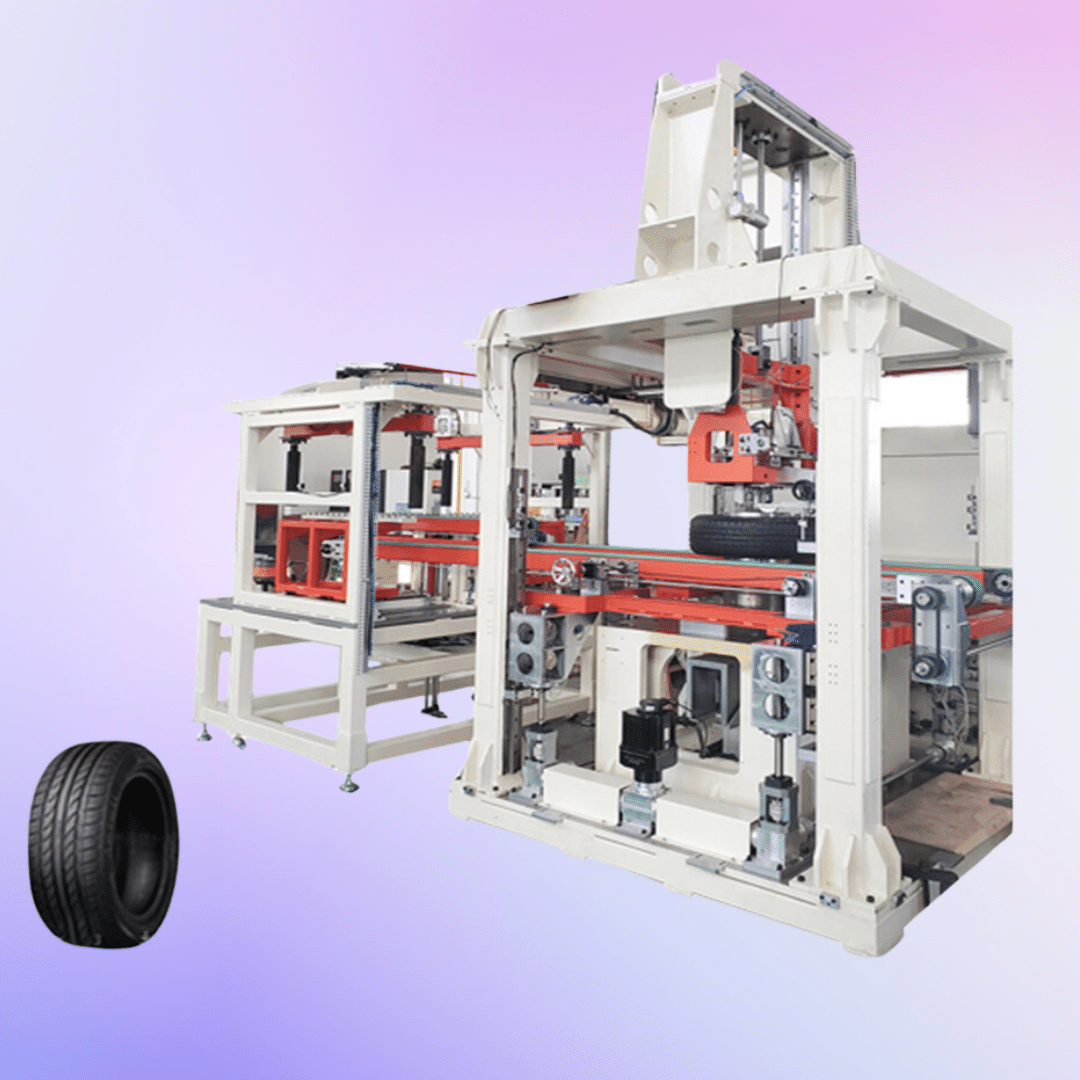

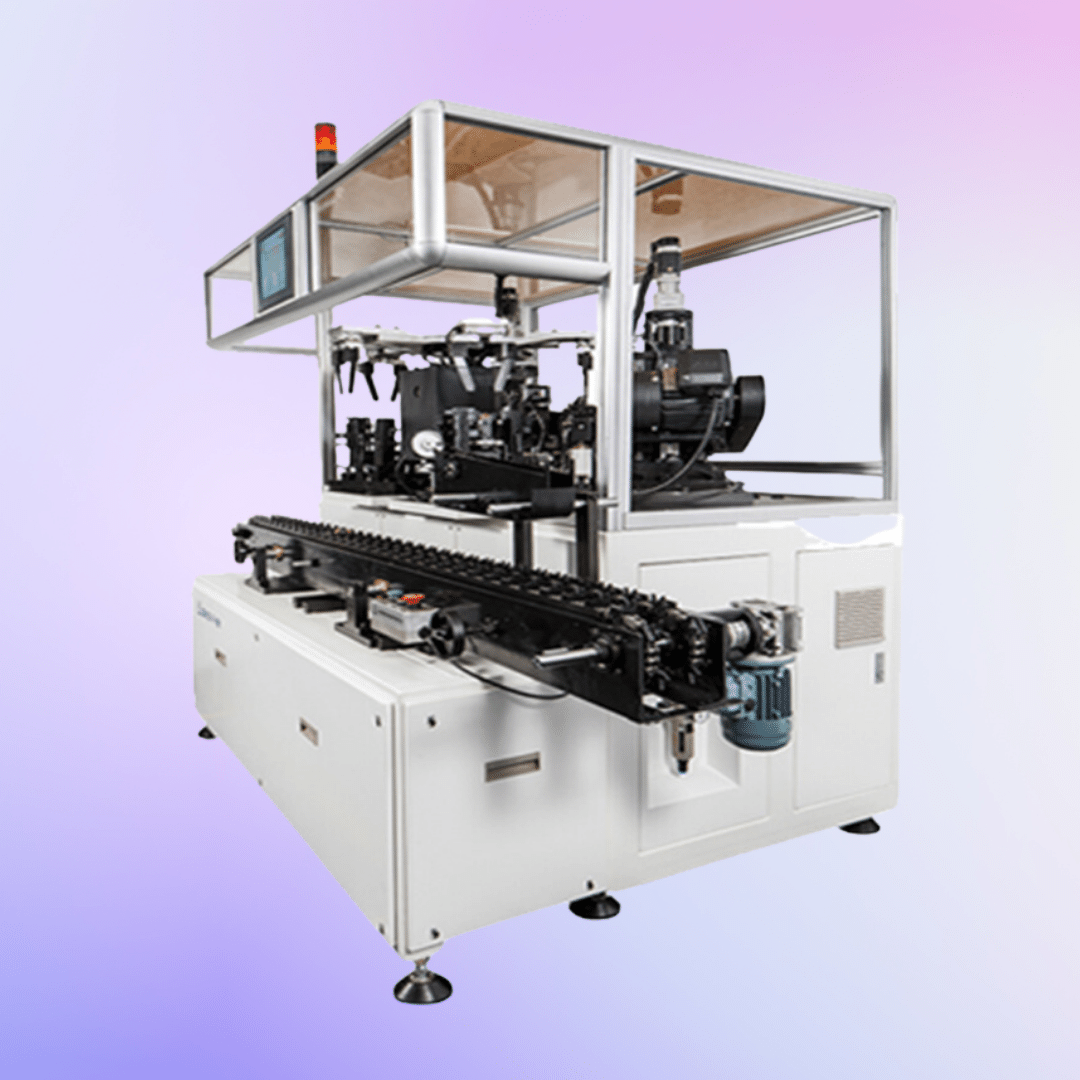

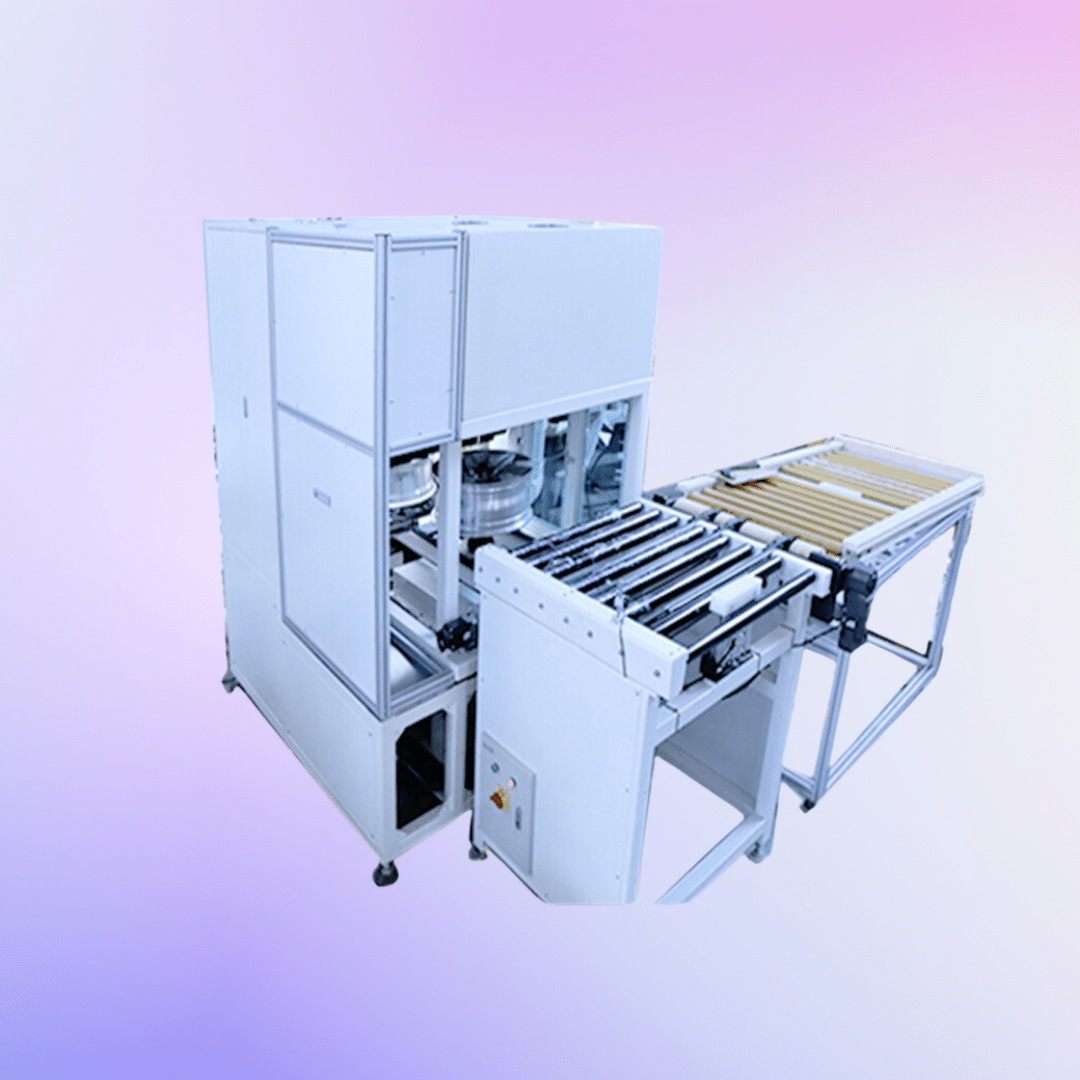

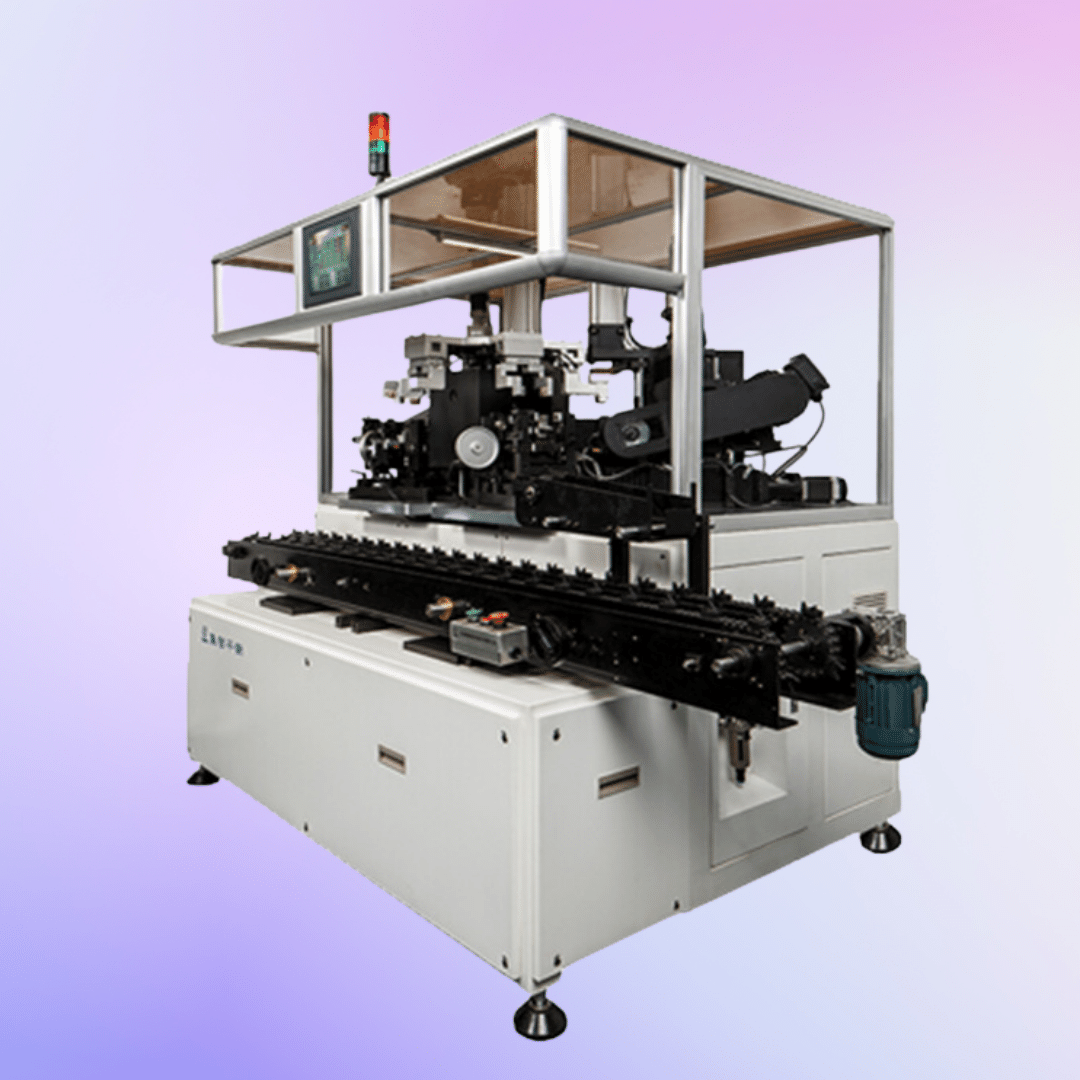

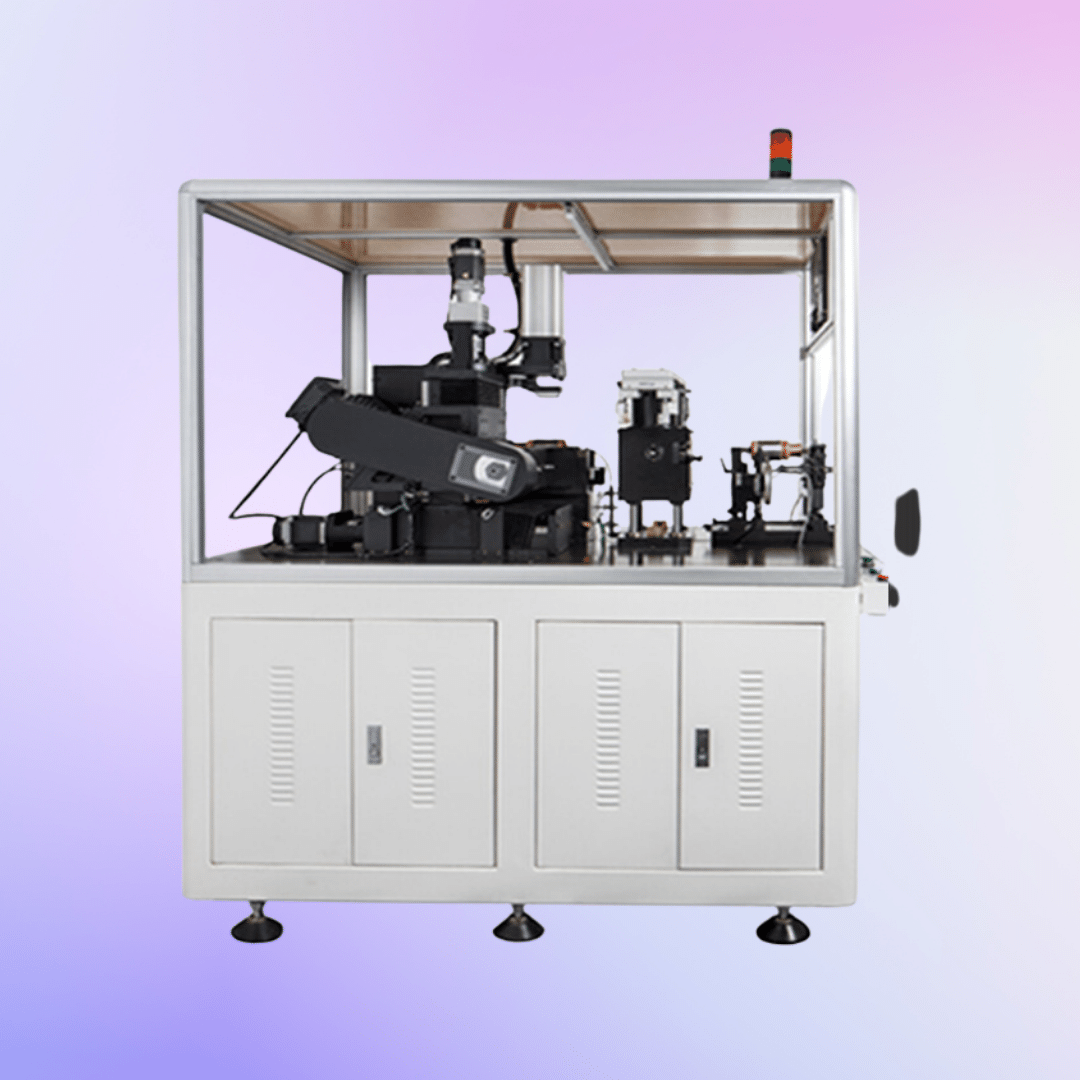

It is applied to the dynamic balance automatic detection system of automobile semi-steel radial tires, and is suitable for on-line detection of static unbalance and dynamic unbalance of semi-steel radial tires.

It is applied to the dynamic balance automatic detection system of automobile semi-steel radial tires, and also capable of automatic identification of tire barcodes, with functions of centering and automatic lubrication

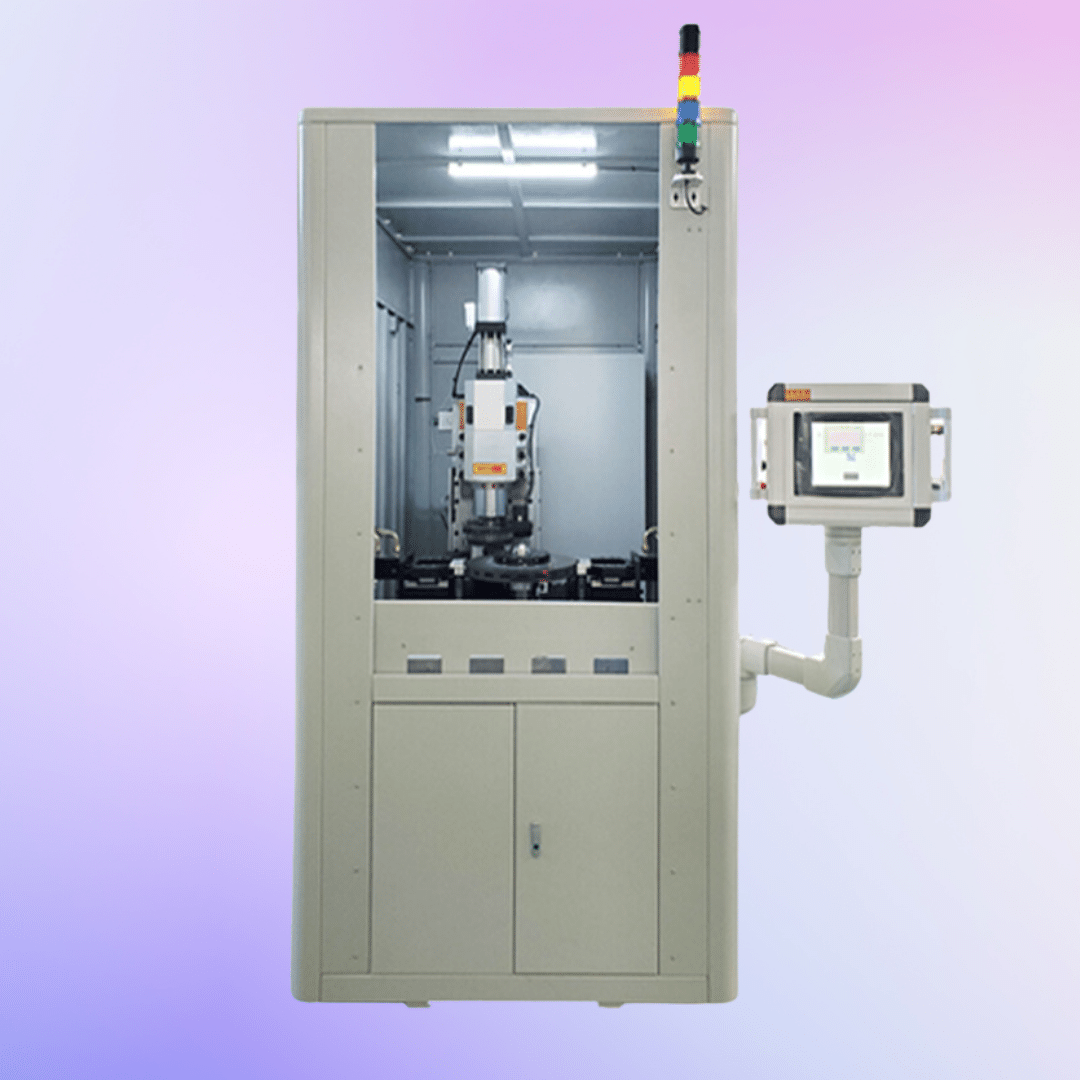

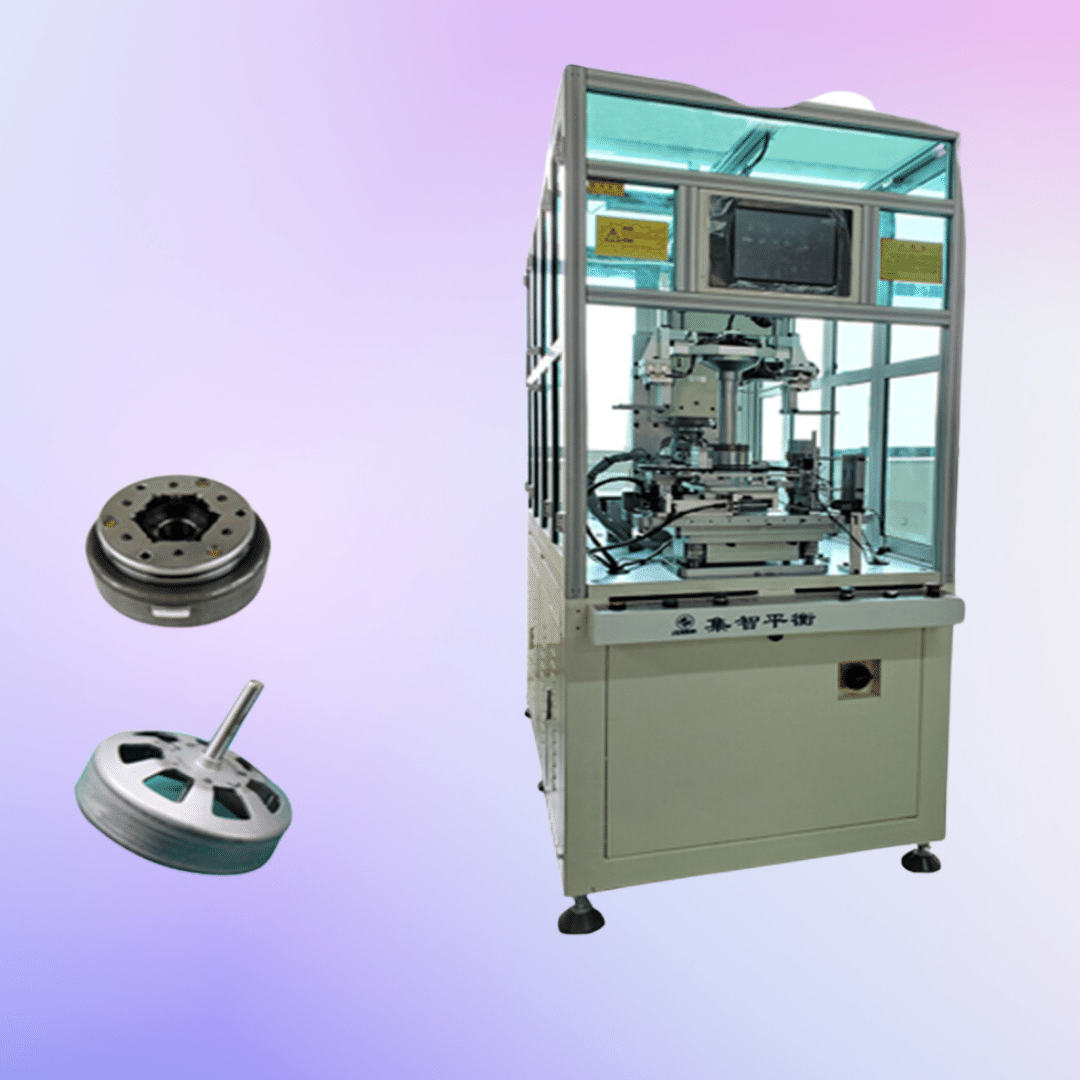

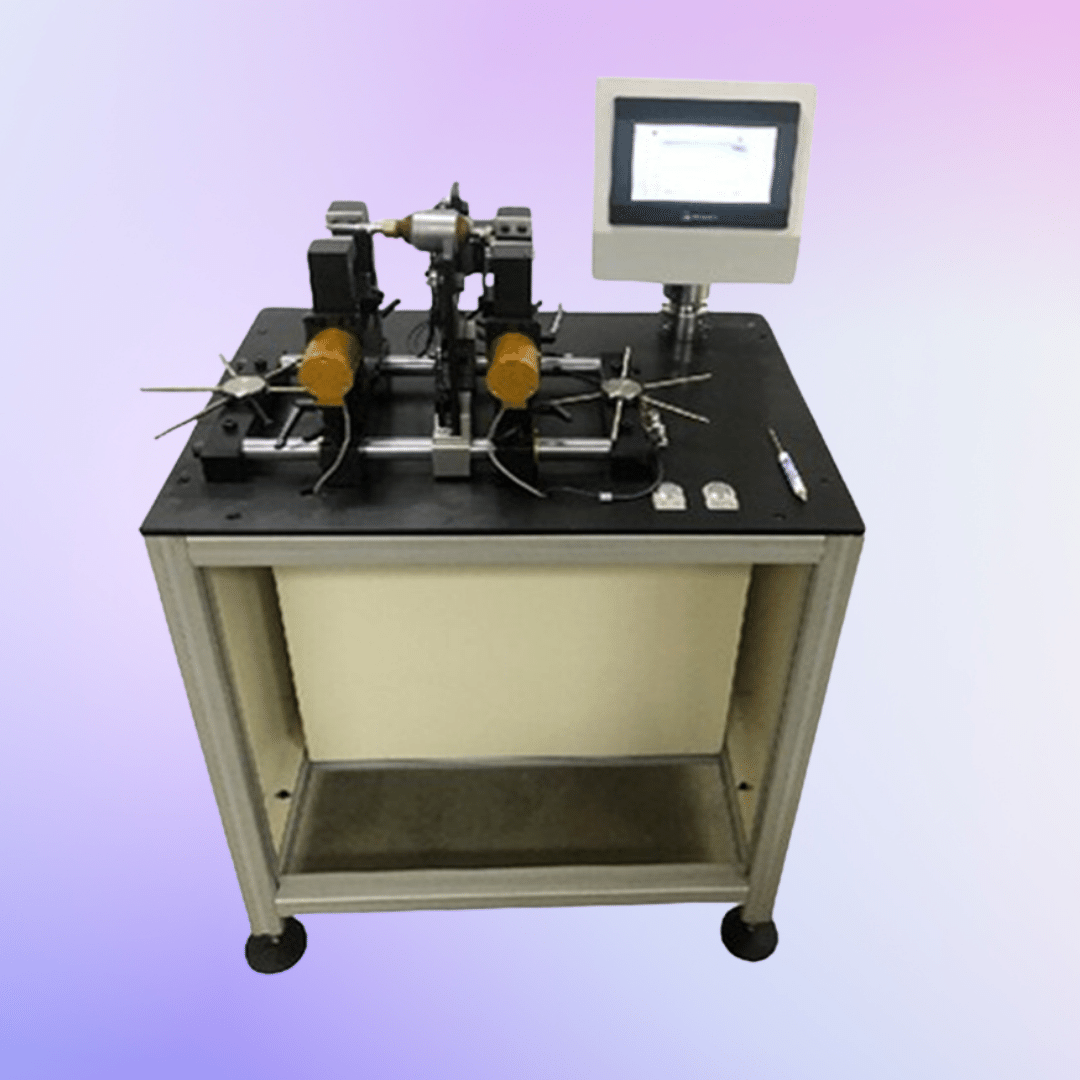

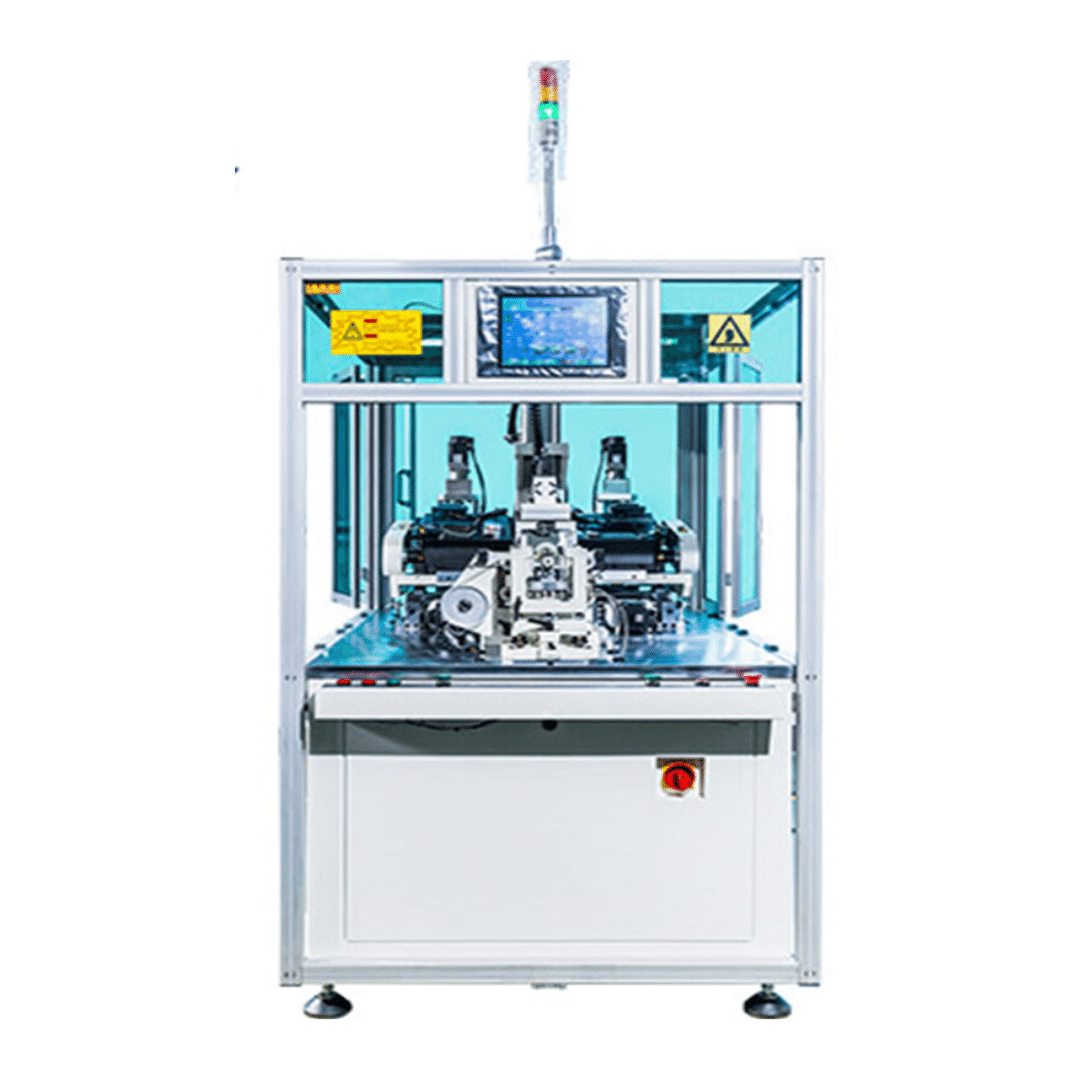

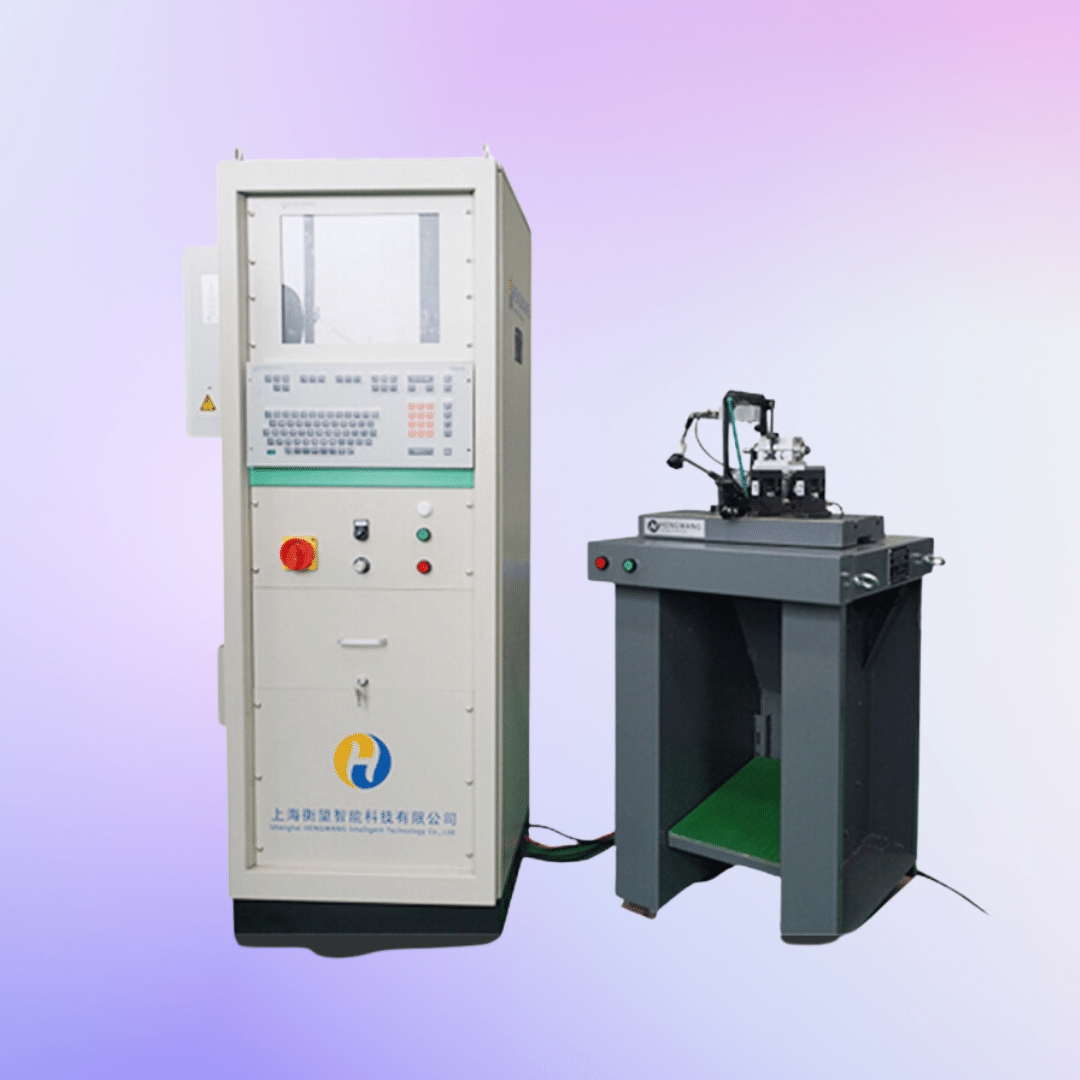

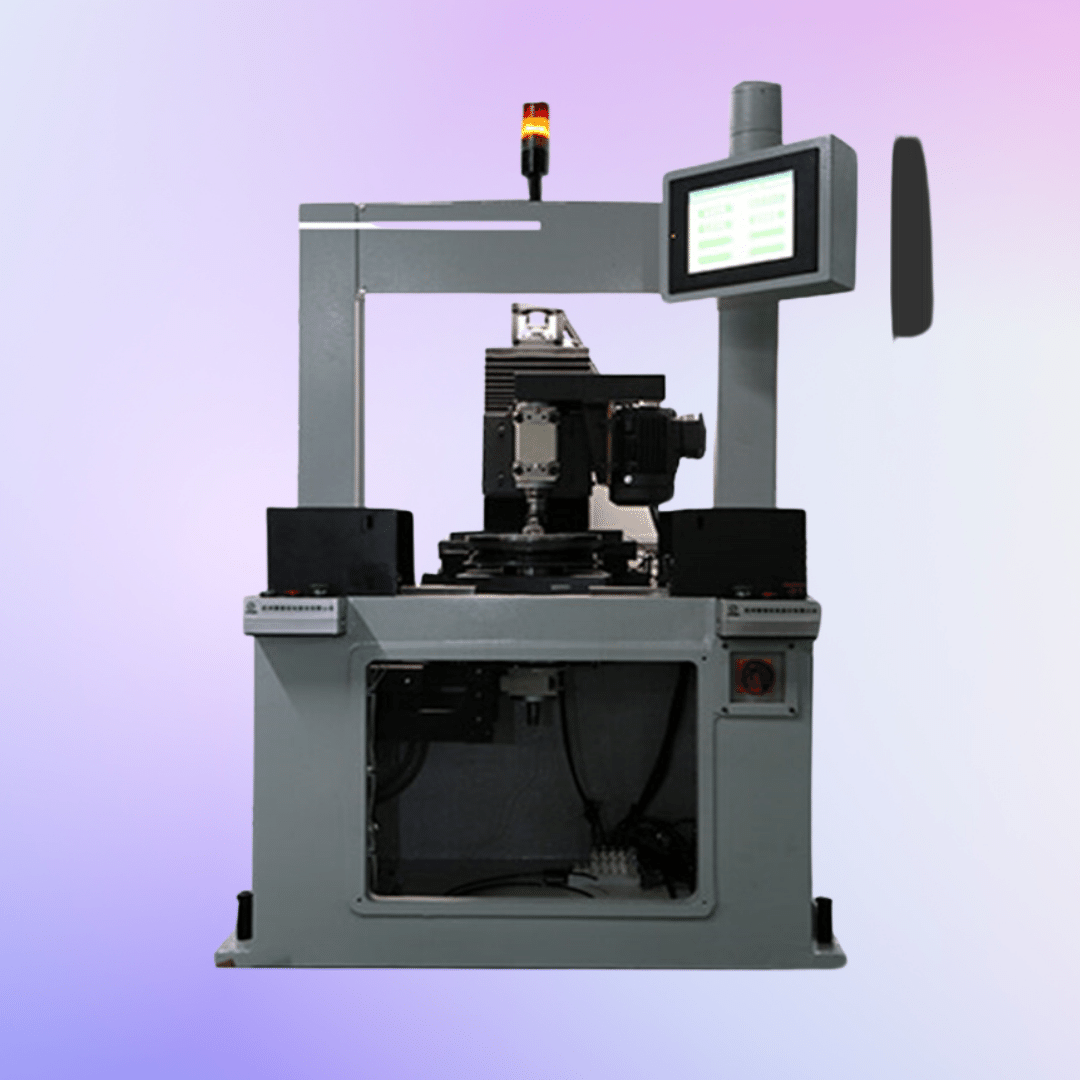

The correction method of this device adopts the electrical zero adjustment method of unbalance, so there is no need to specially make a standard rotor with zero unbalance.

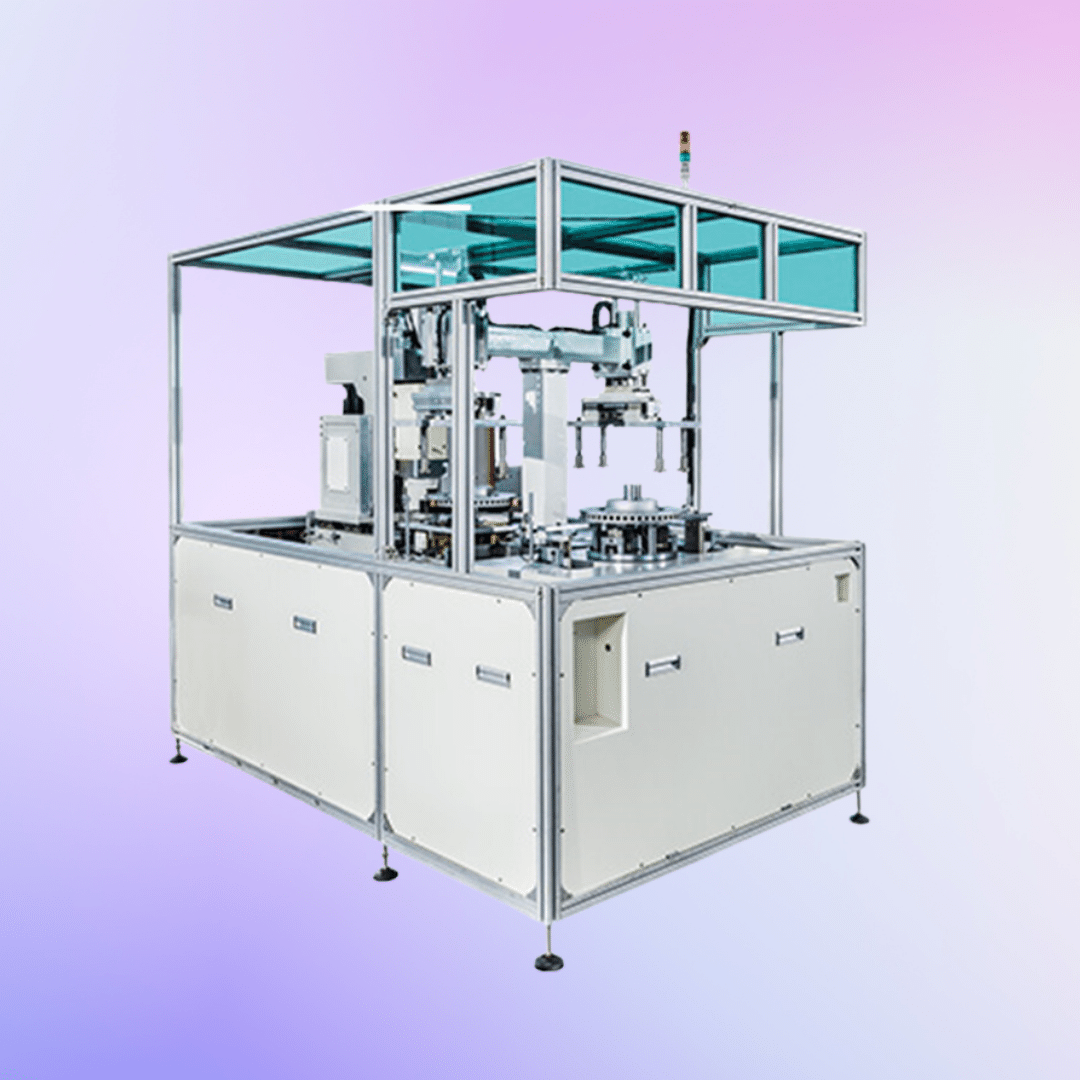

It can be operated as a stand-alone machine, can be connected to a fully automatic and Soft support high-precision measurement system, high accuracy of measurement data and good repeatability

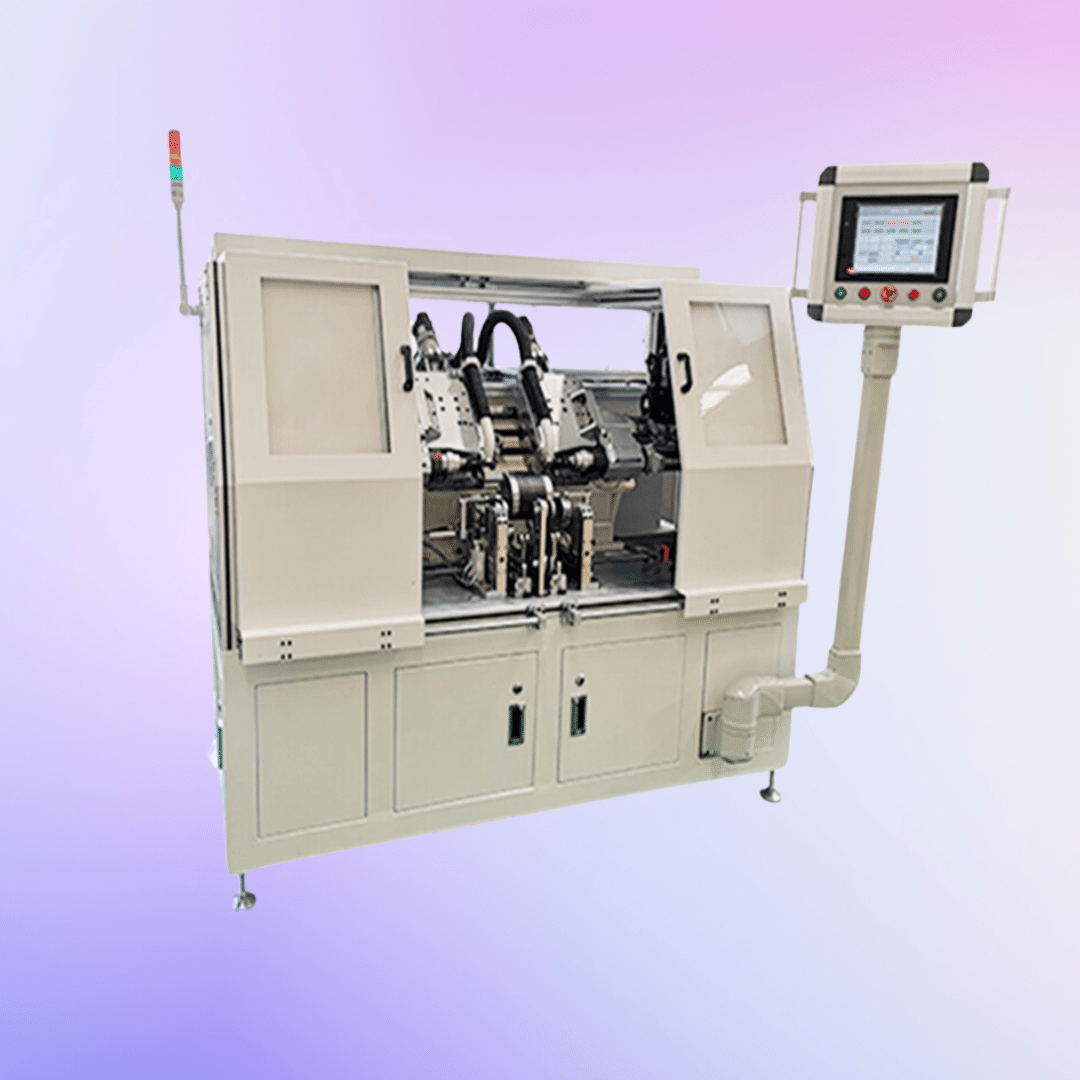

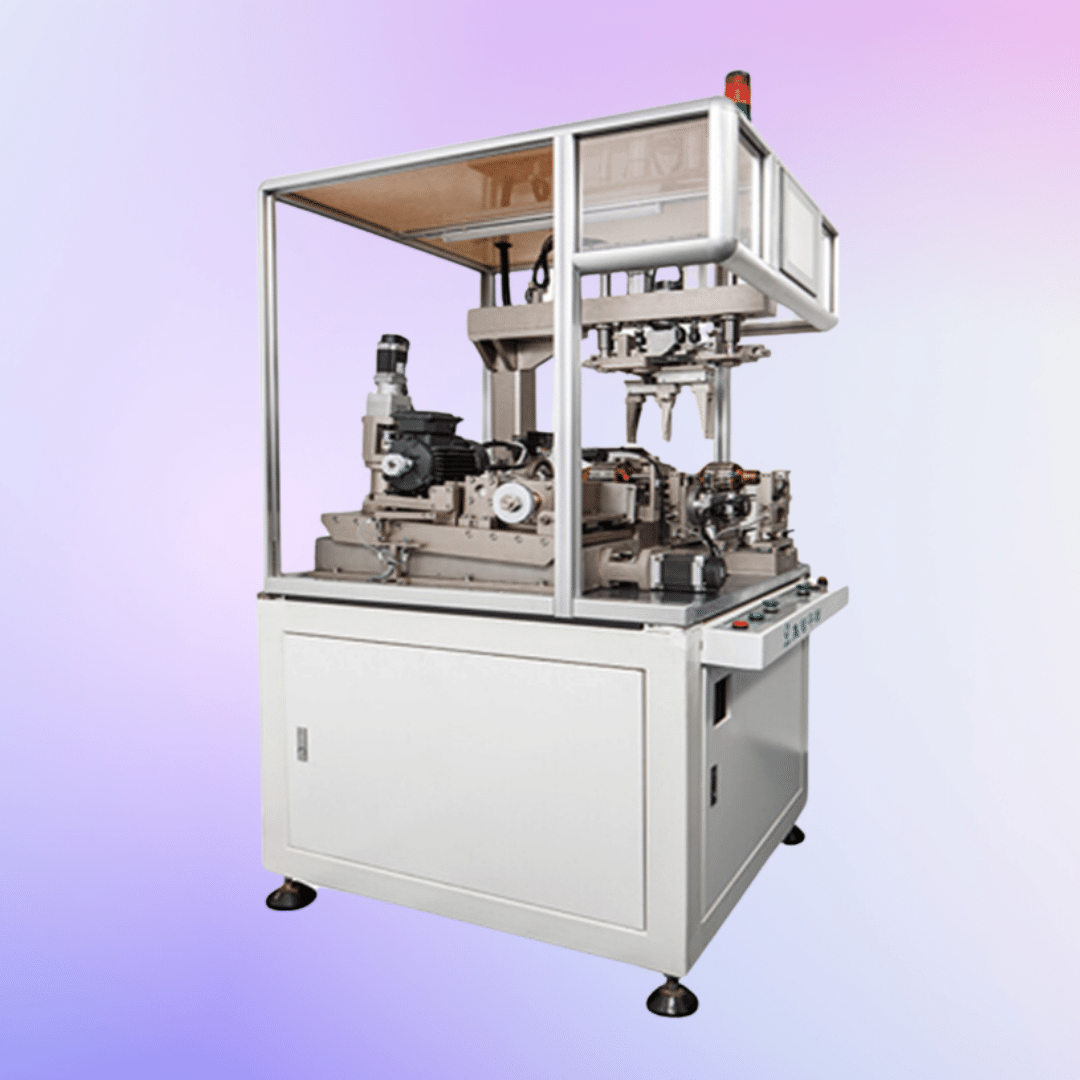

This machine have High efficiency, the working cycle of the equipment (initial test + milling + retest) can reach 40 seconds, and the test and milling are carried out at the same time.

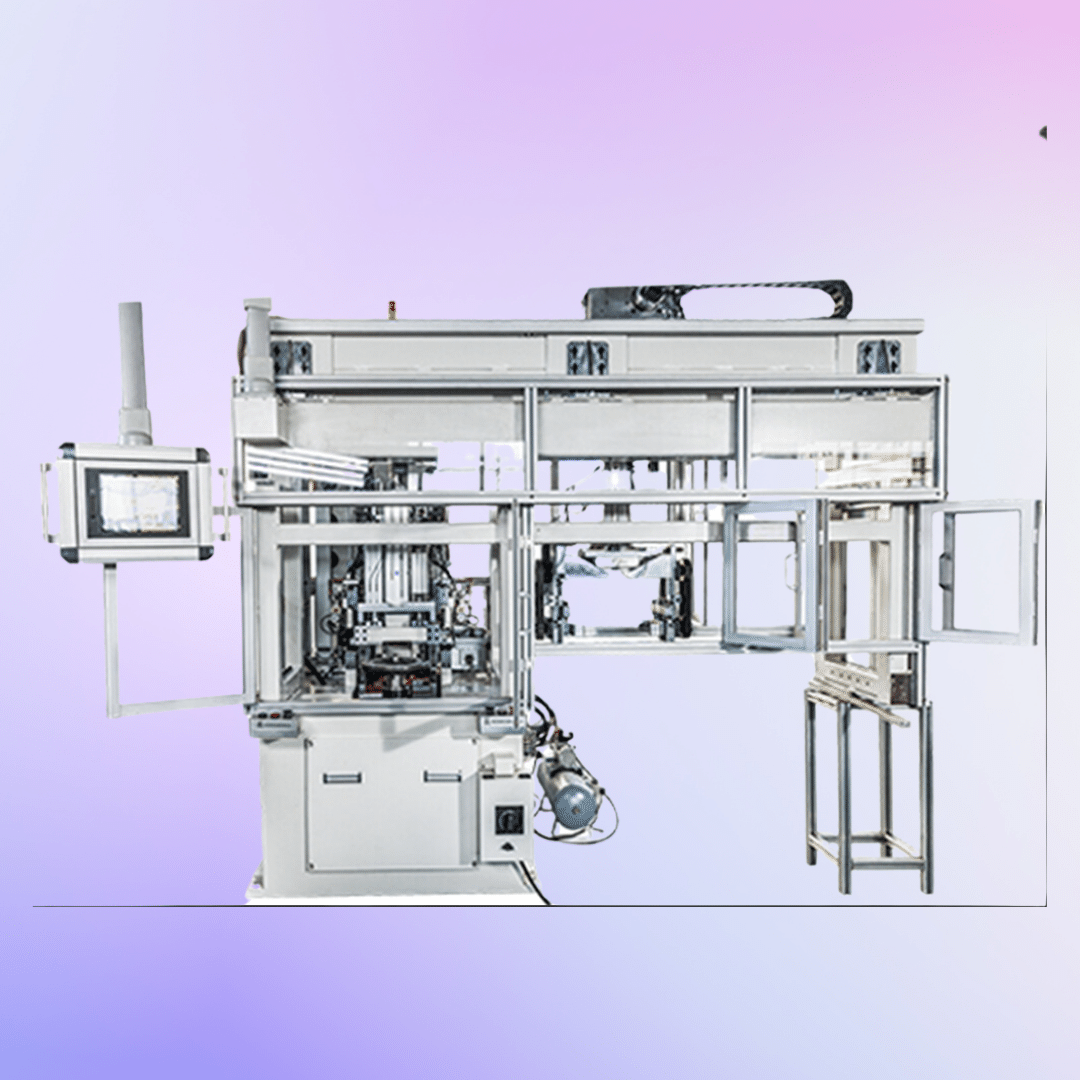

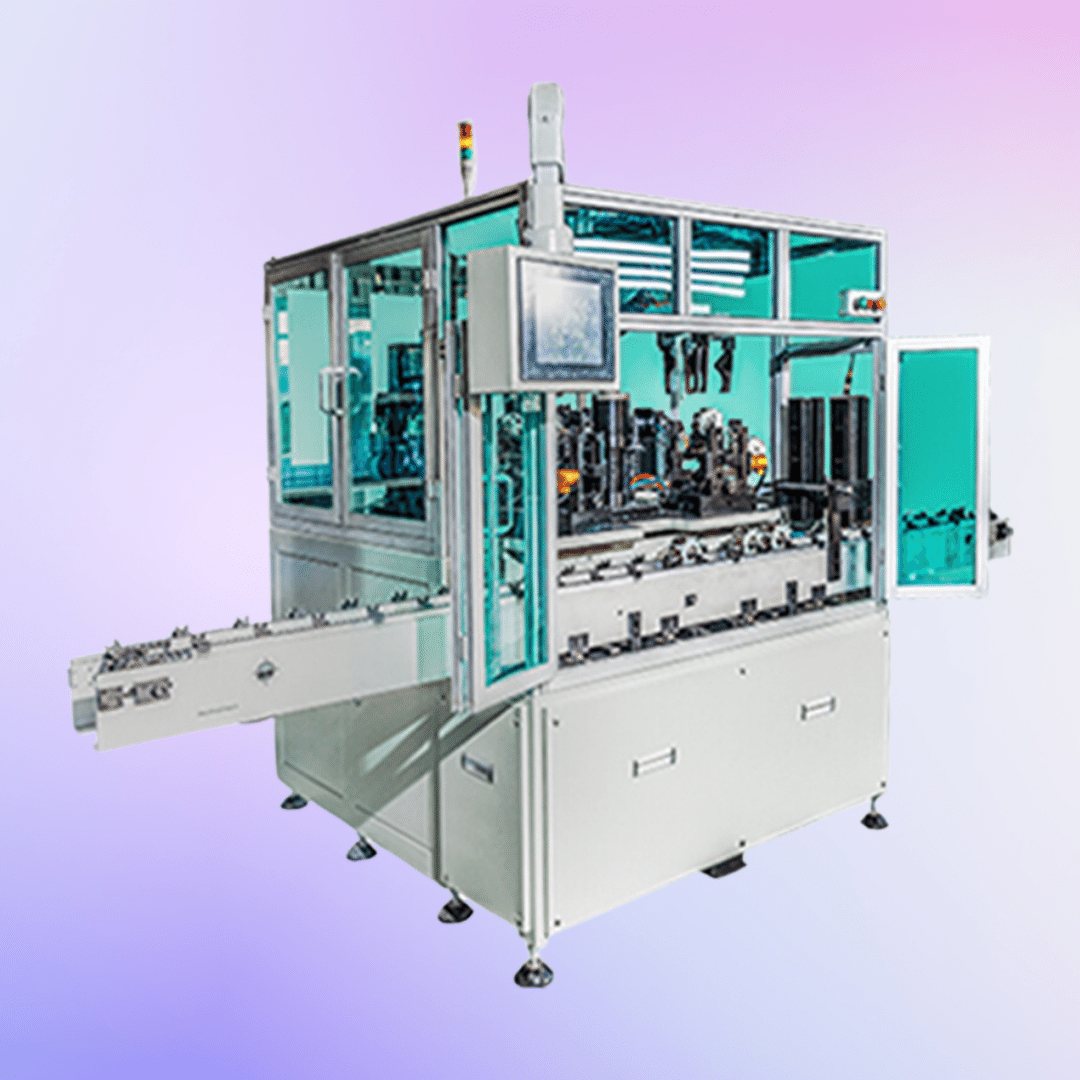

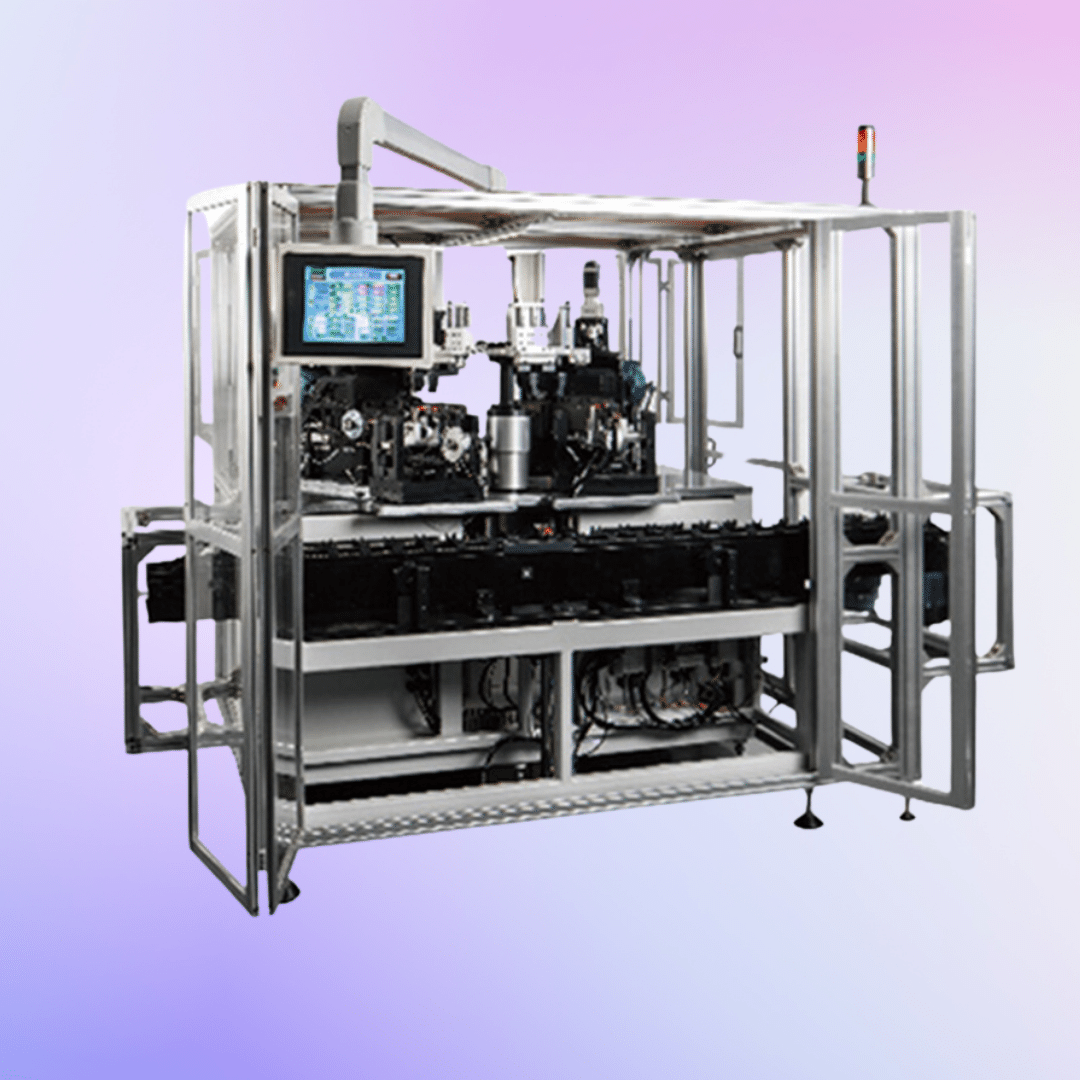

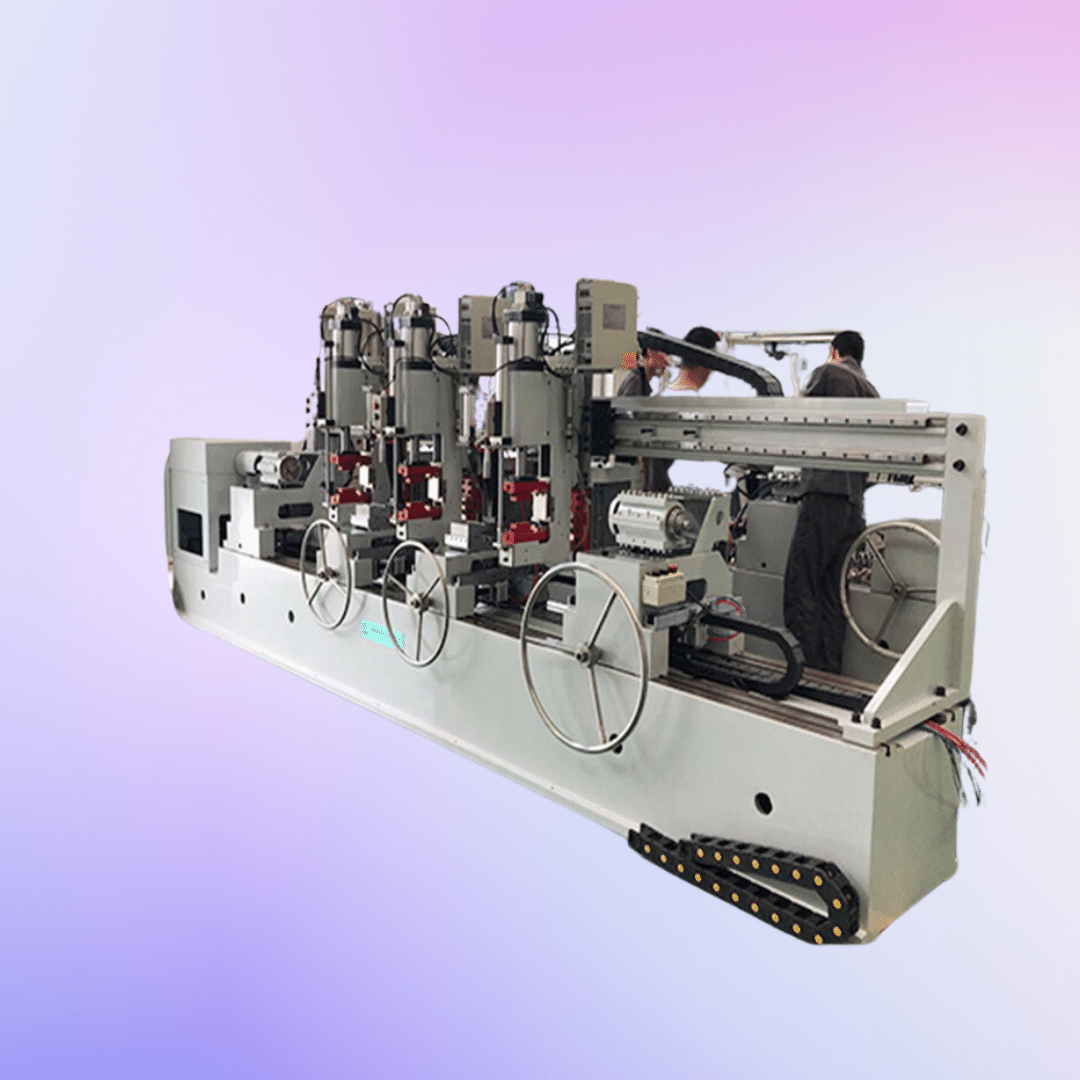

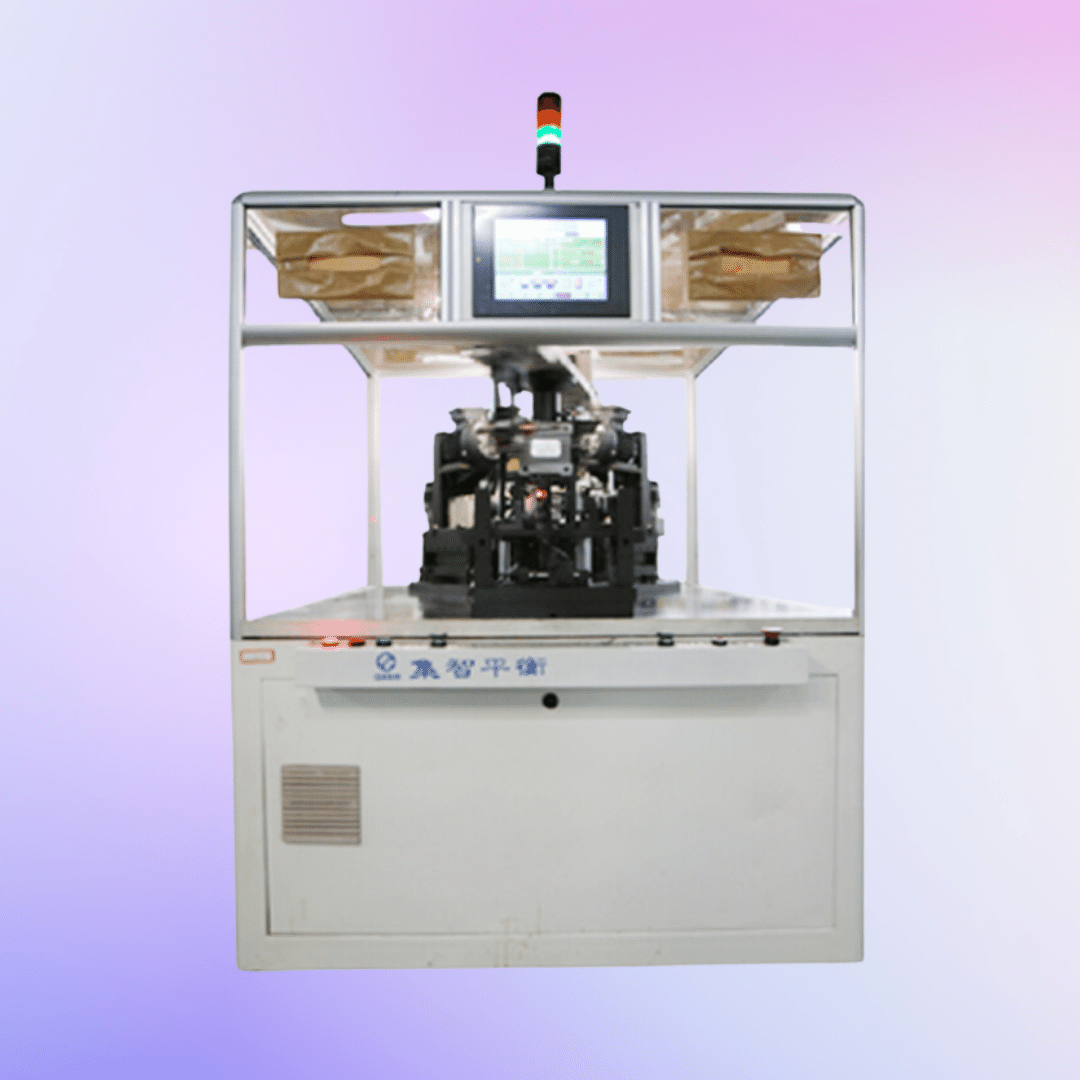

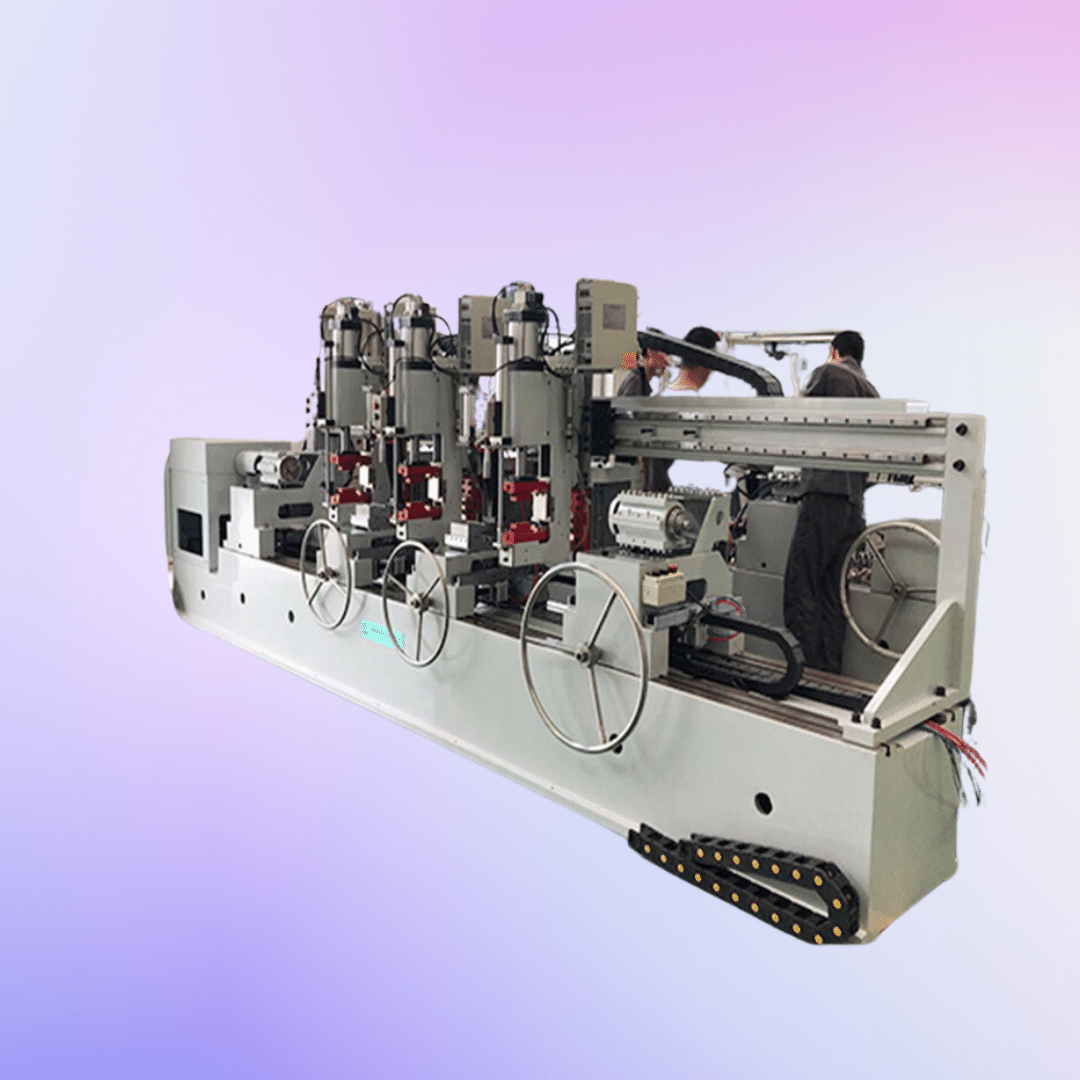

Economical five-station automatic rotor dynamic balancing machine have Soft support high-precision measurement system, high accuracy of measurement data and good repeatability.

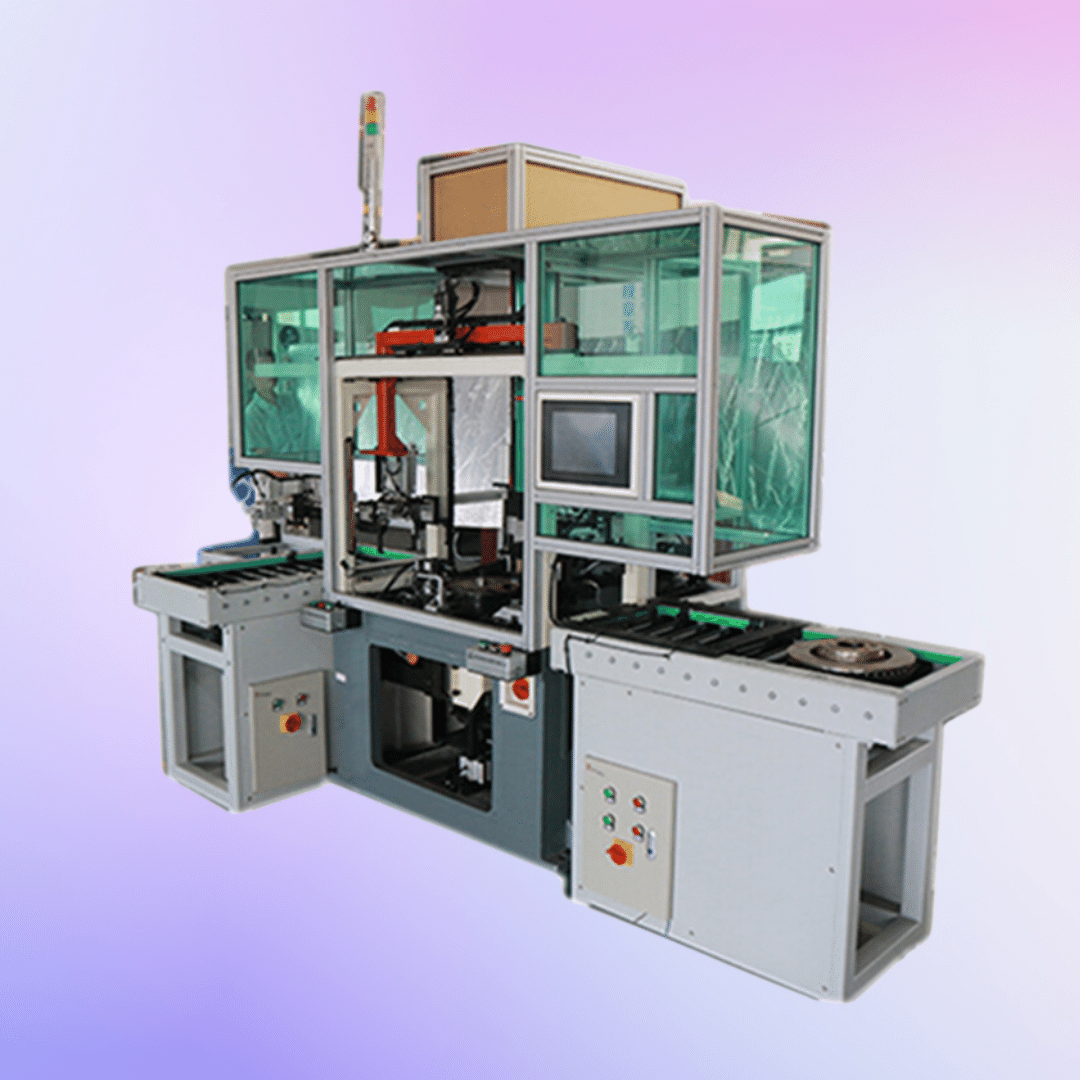

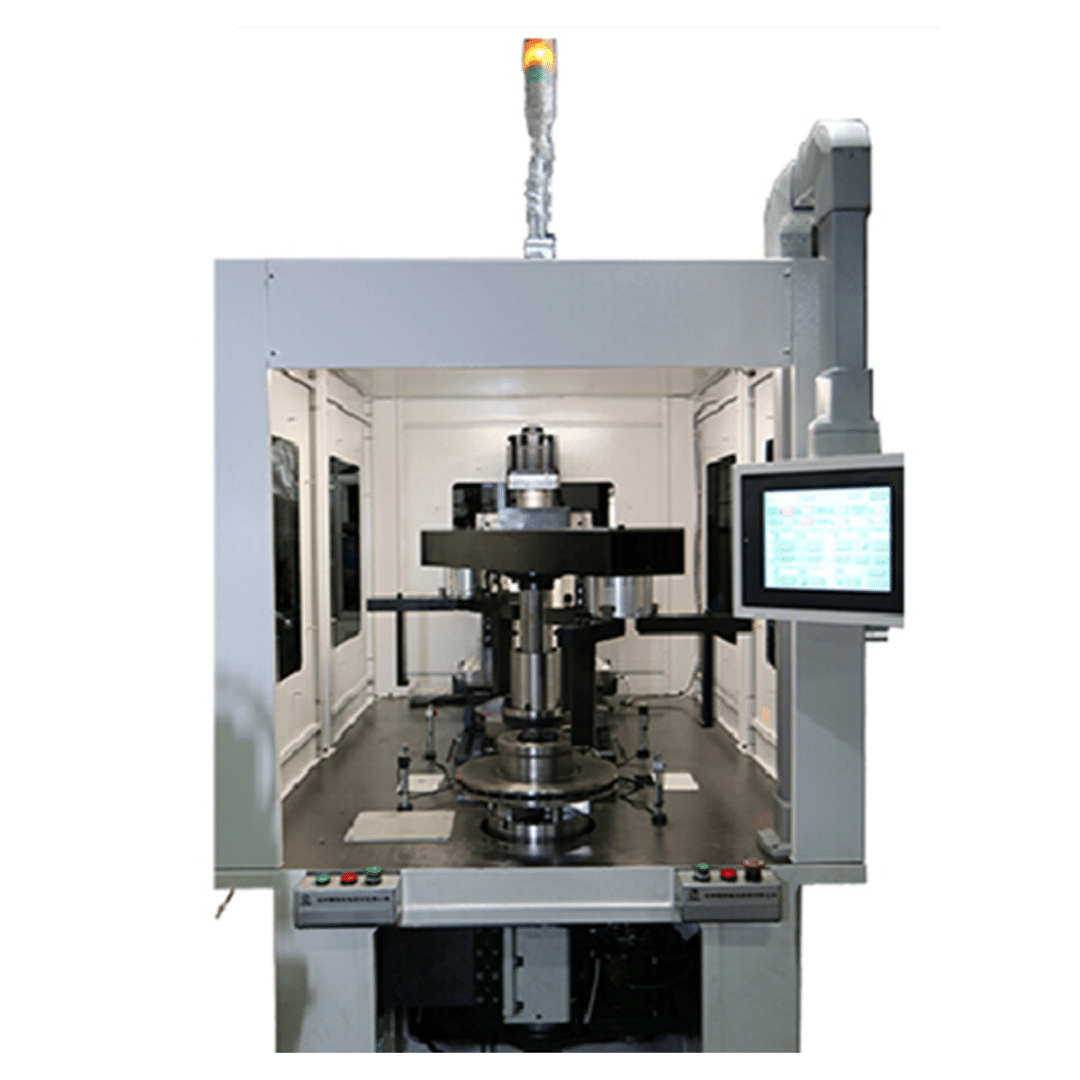

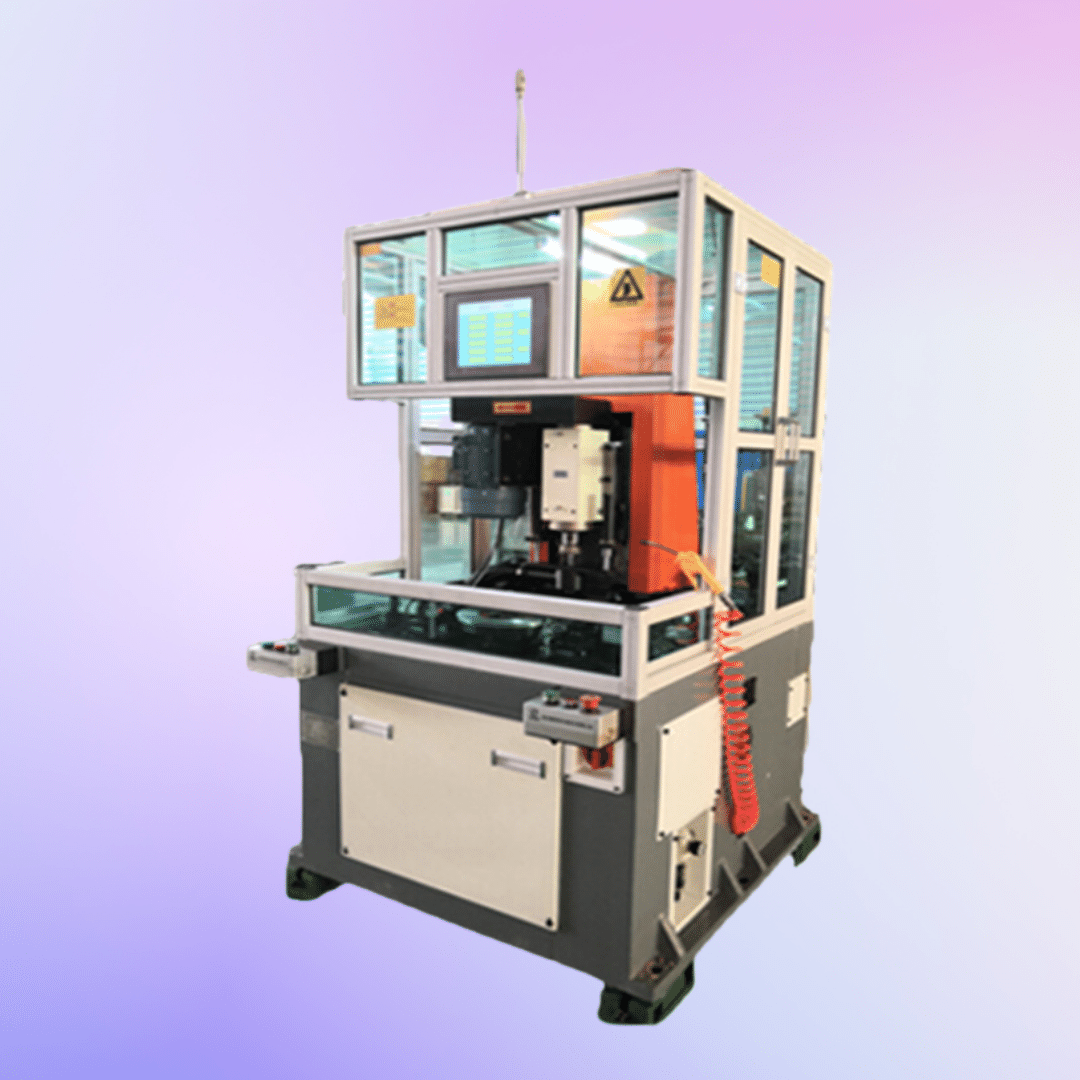

Single-station automatic balancing machine ( BPXDX-1W-C ) is suitable for brake discs, brake drums and other disc parts with a central hole or shaft and an outer diameter of φ300-φ550mm.

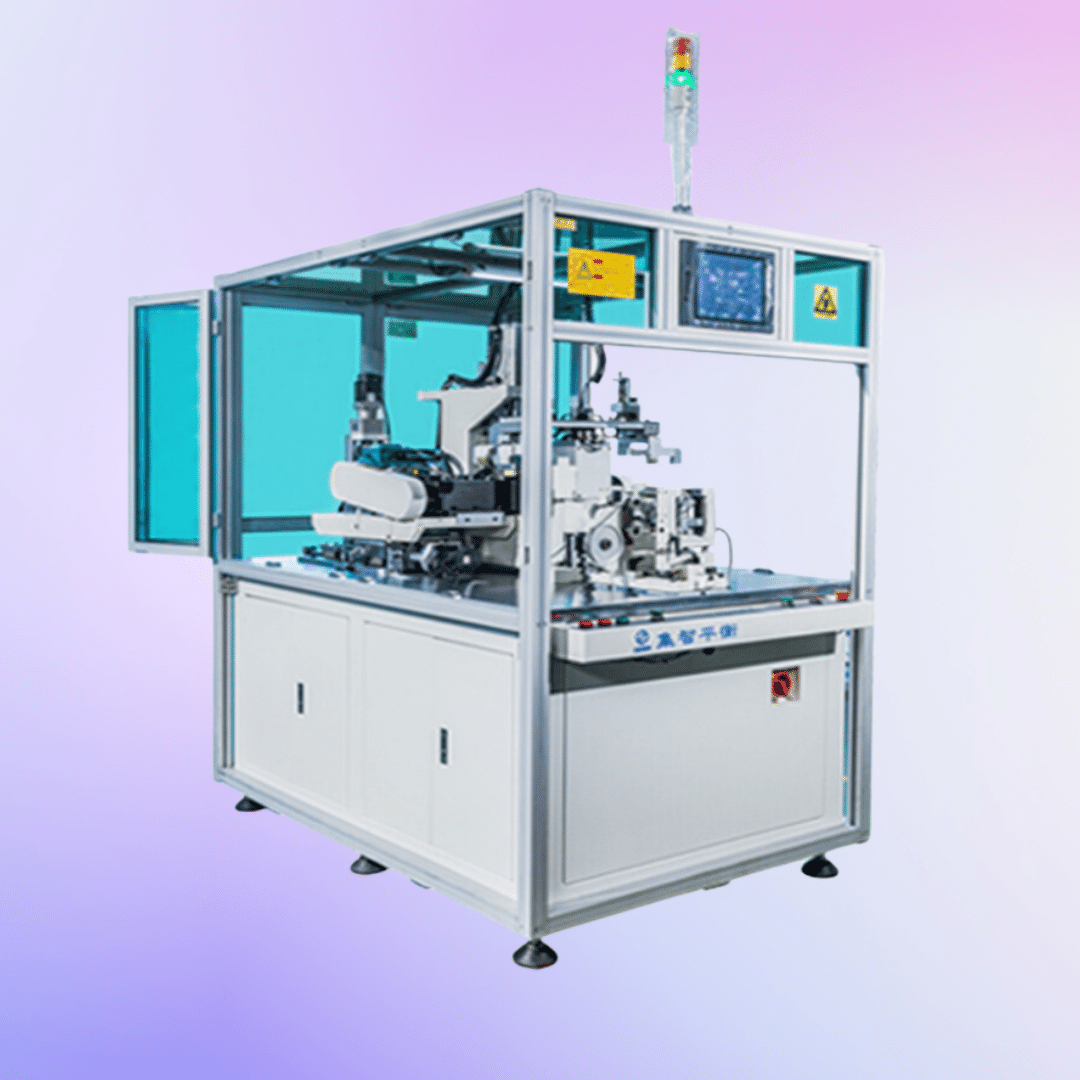

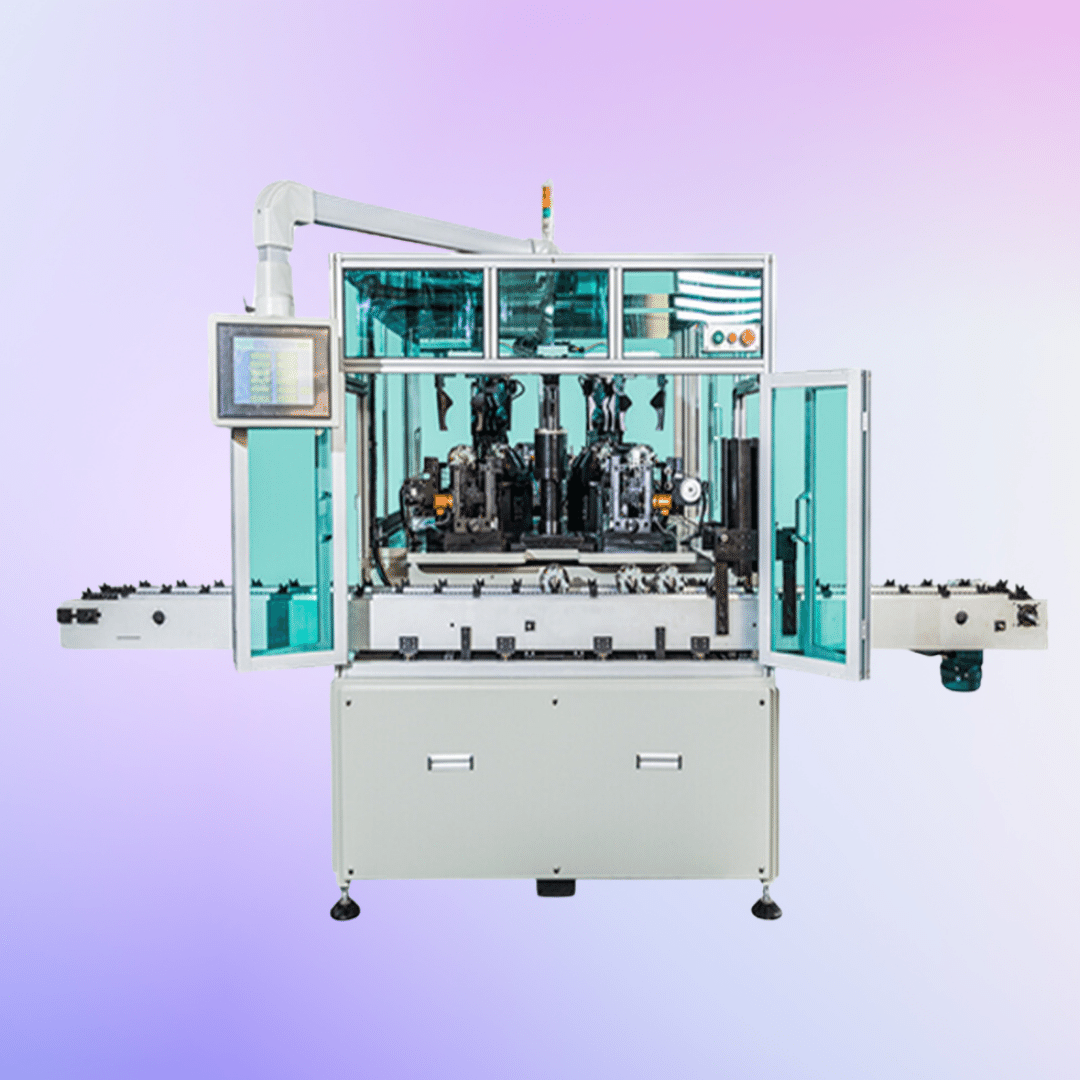

It can be equipped with a separate automatic assembly line, or it can be connected with a fully automatic rotor and have wide range of applications, fast type change, suitable for quick change of small batches and multiple varieties.

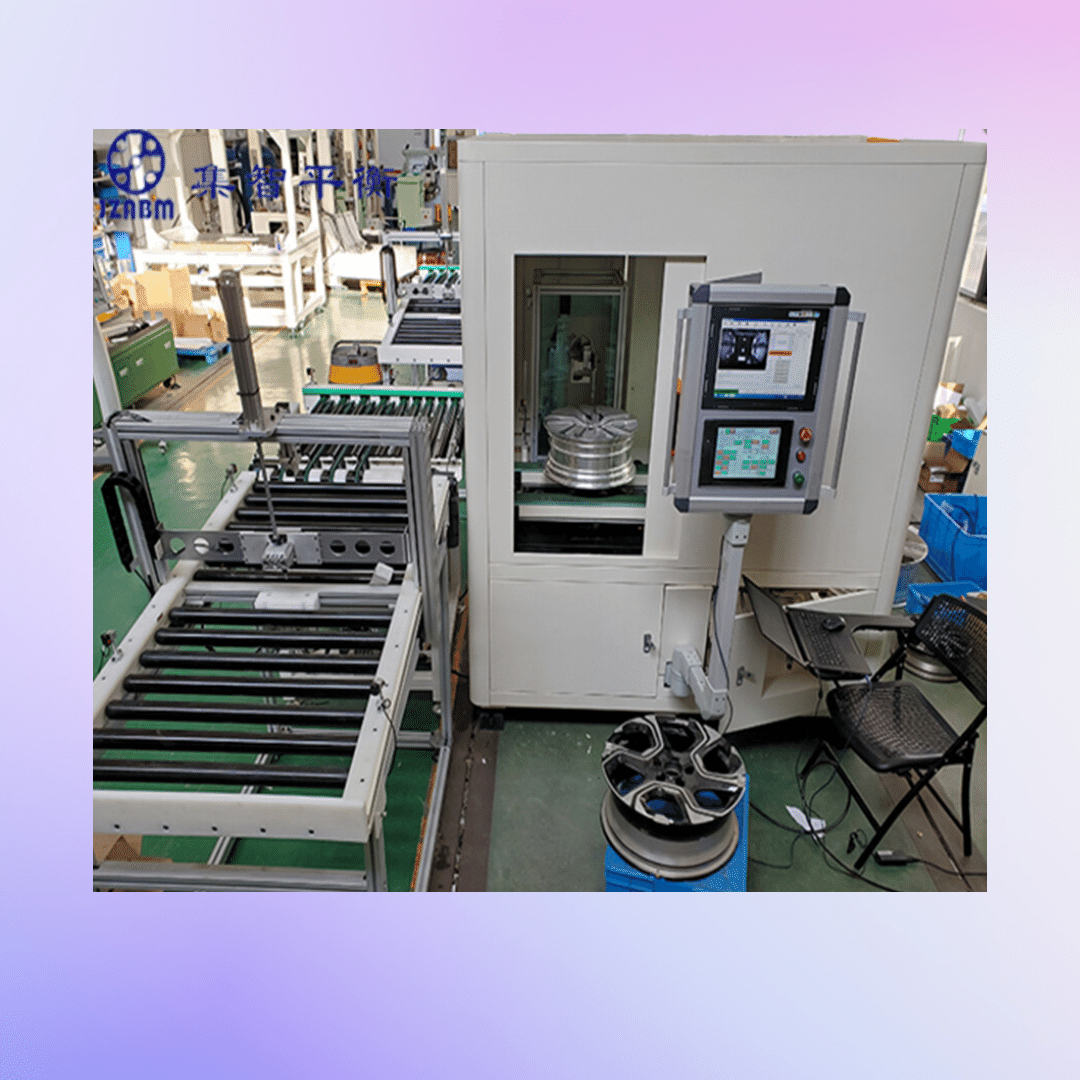

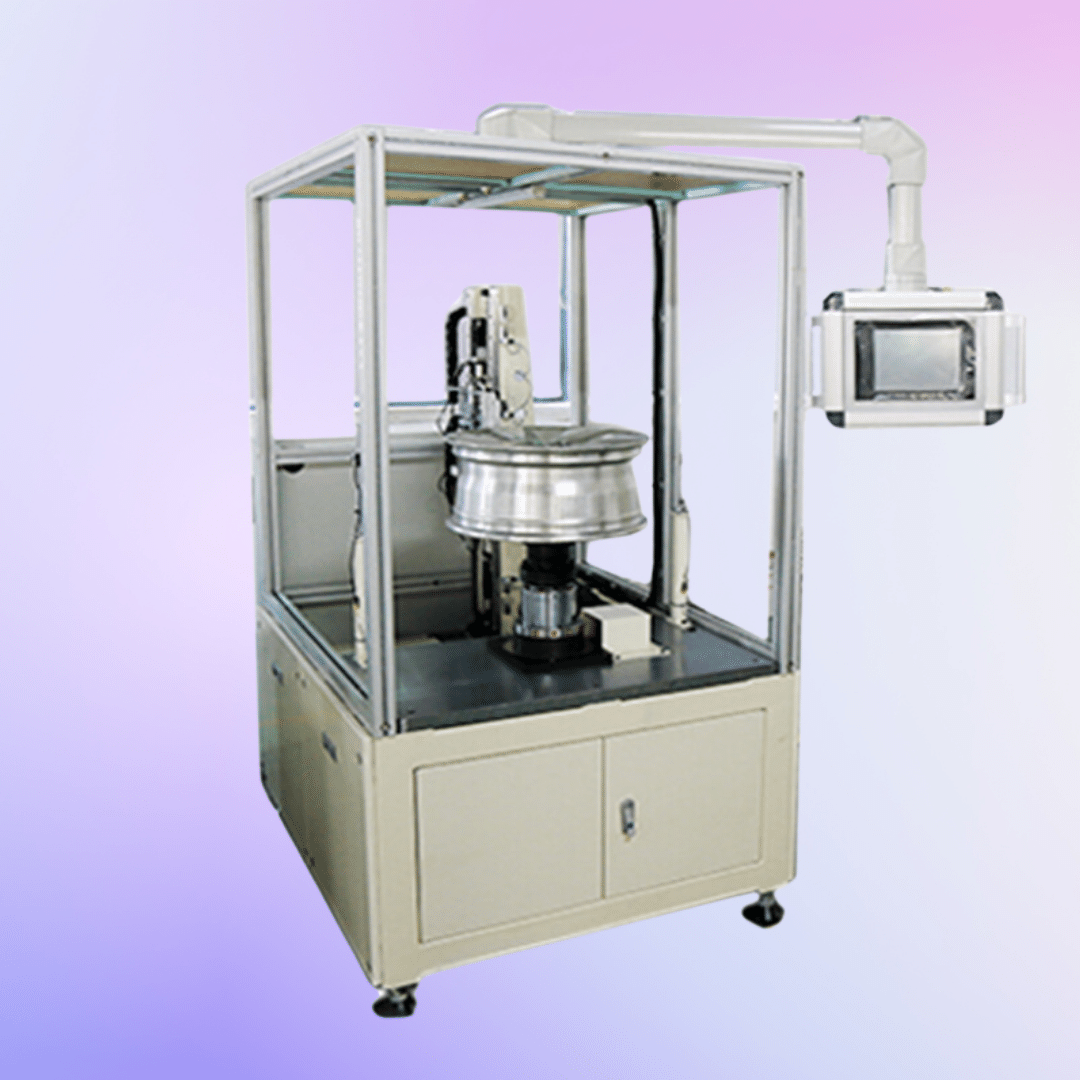

It is equipped with a vision-based model recognition system, which can dynamically retrieve detection parameters according to the wheel hub model, and is suitable for mixed-line production.

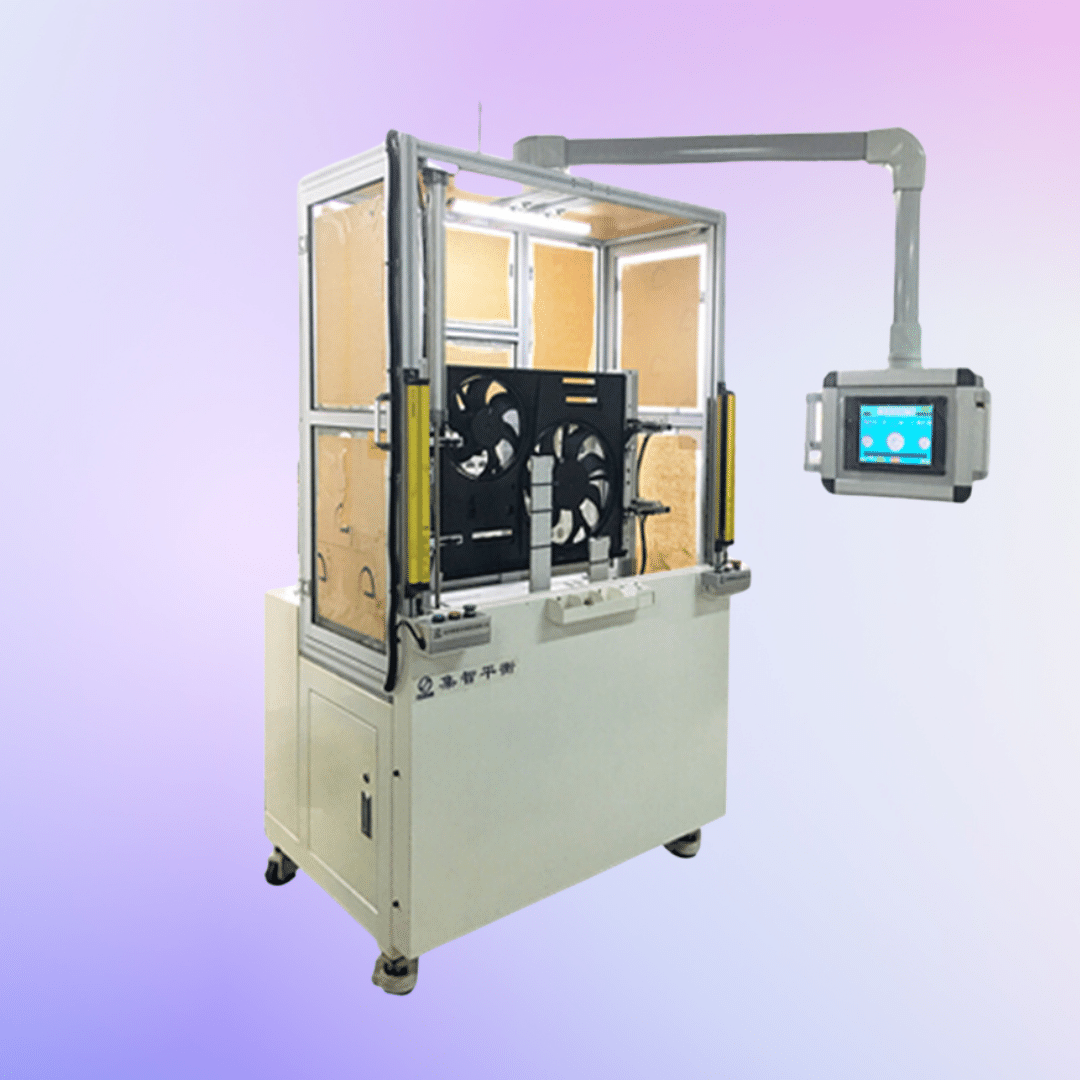

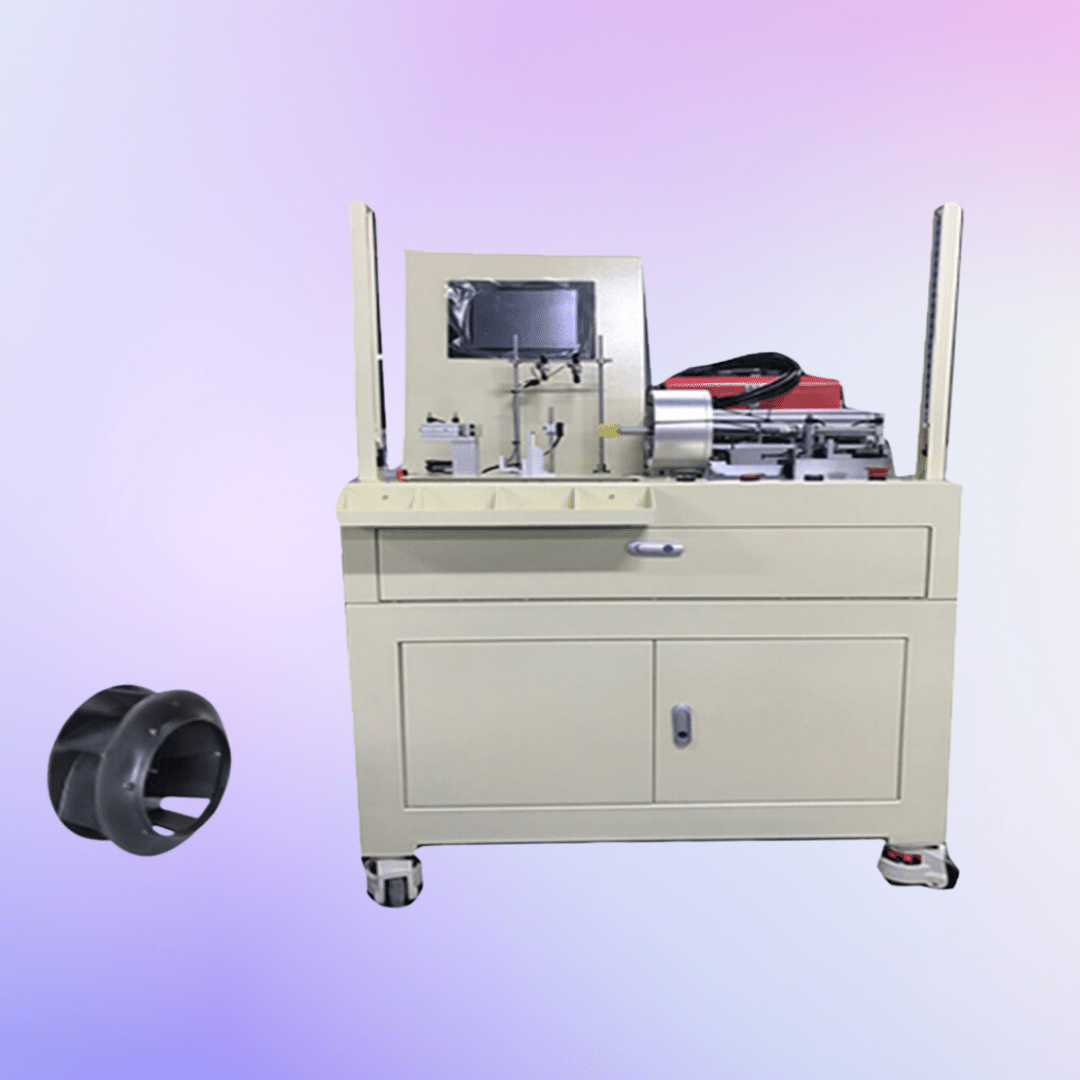

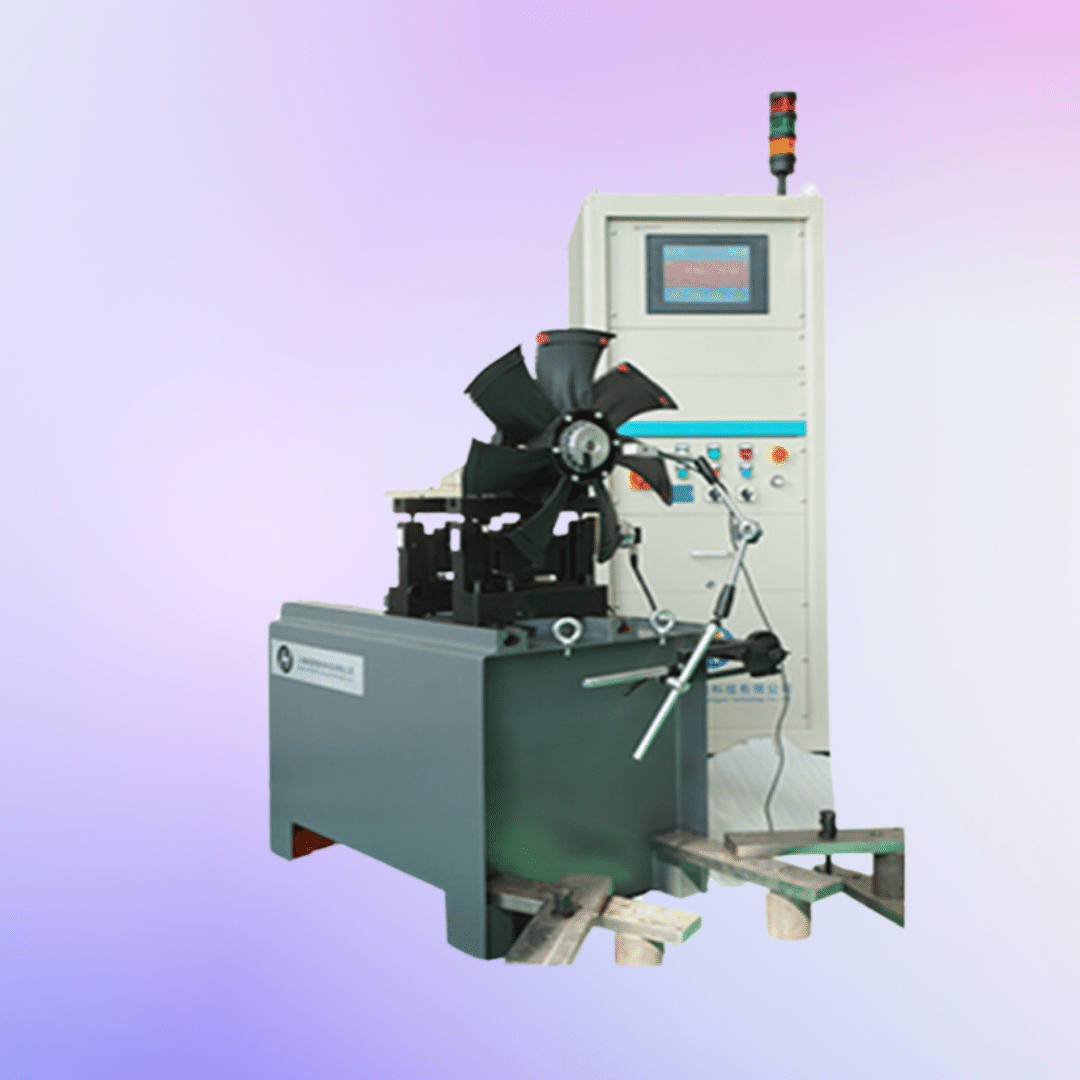

The fan balancing machine is suitable for dynamic balance measurement of automobile cooling fans, and adopts a self-driven method the soft support high-precision measurement system has high measurement data accuracy and good repeatability.

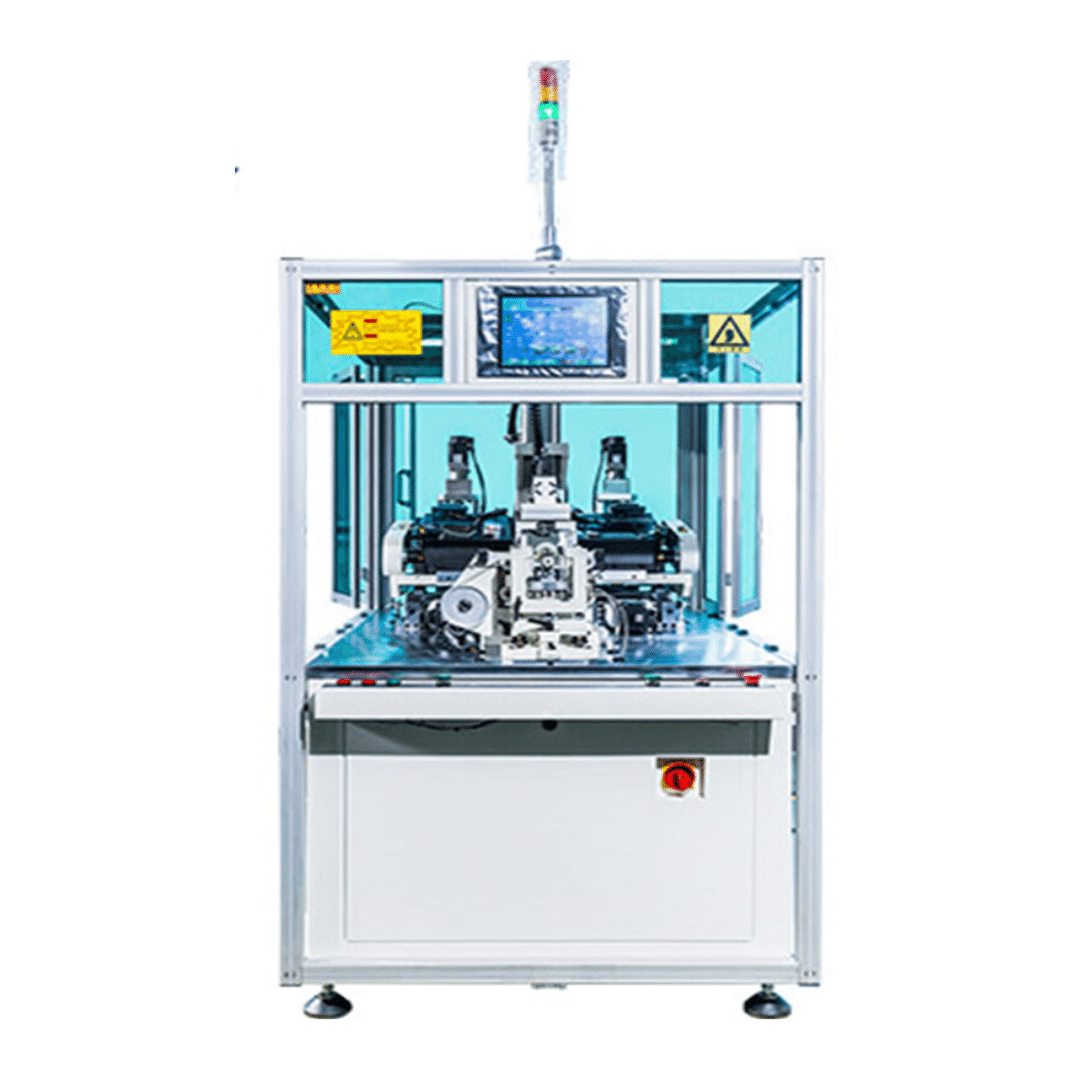

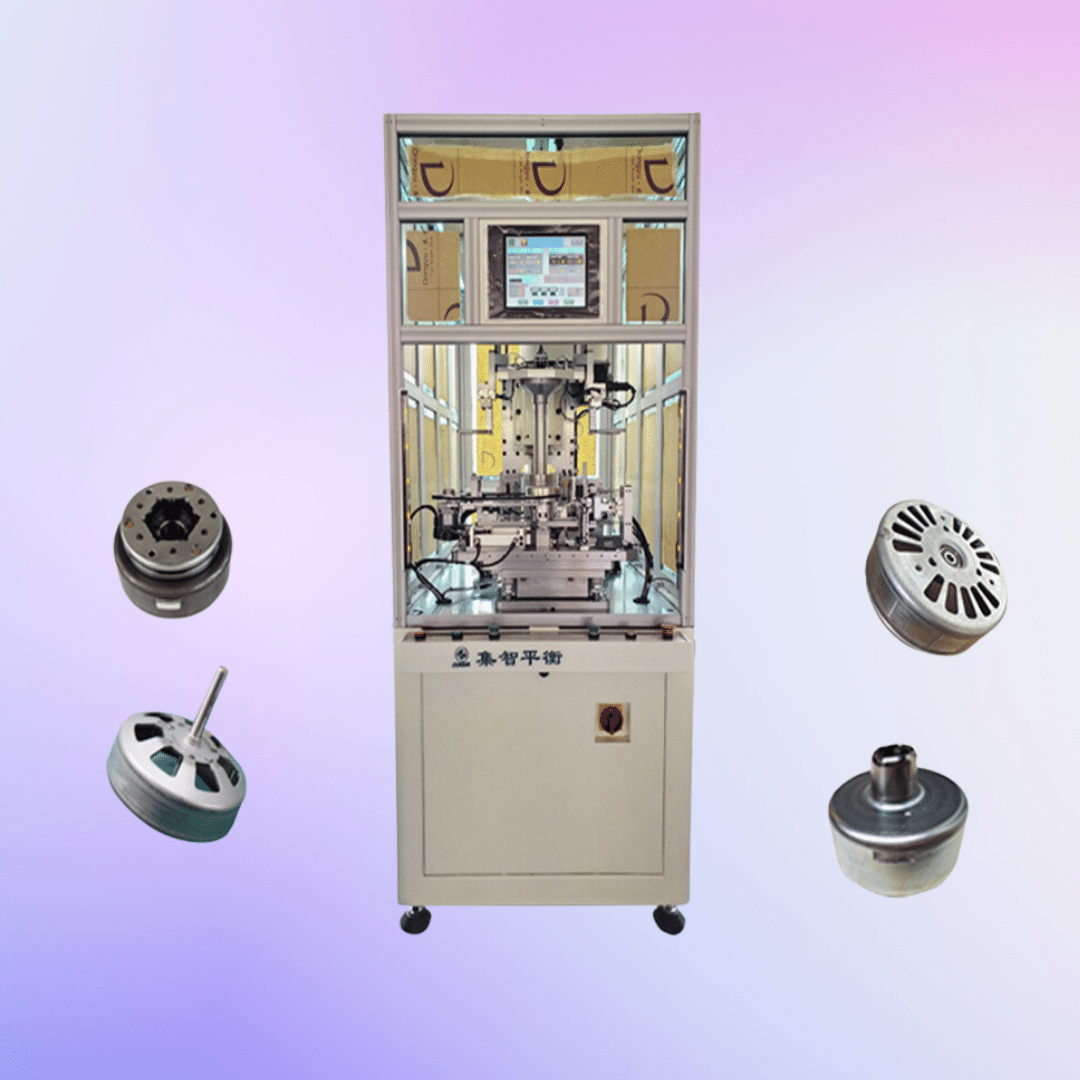

Compatible with vertical double-sided dynamic balance correction of shaftless external rotor; fully automatic measurement of motor external rotor deweighting dynamic balancing machine equipment.

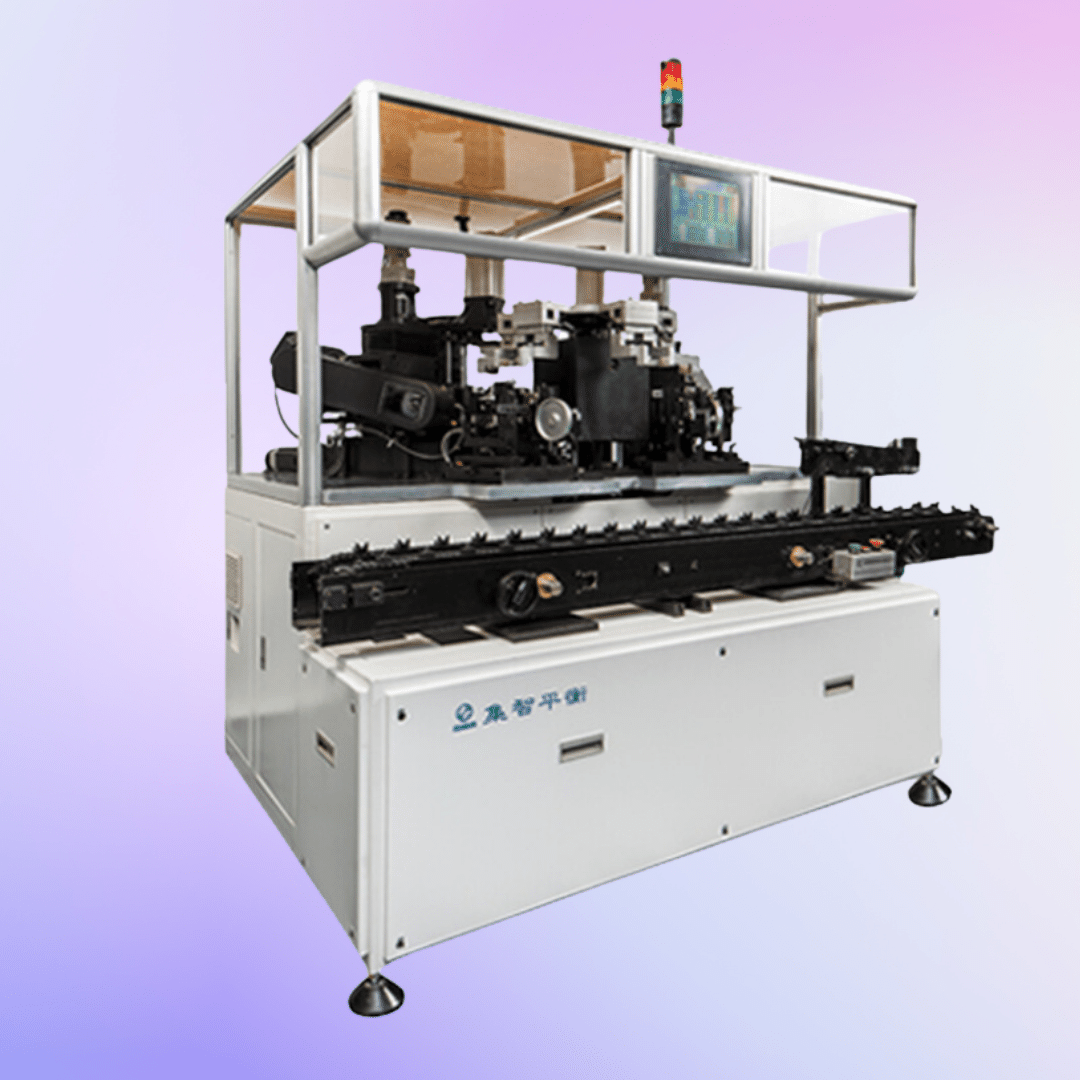

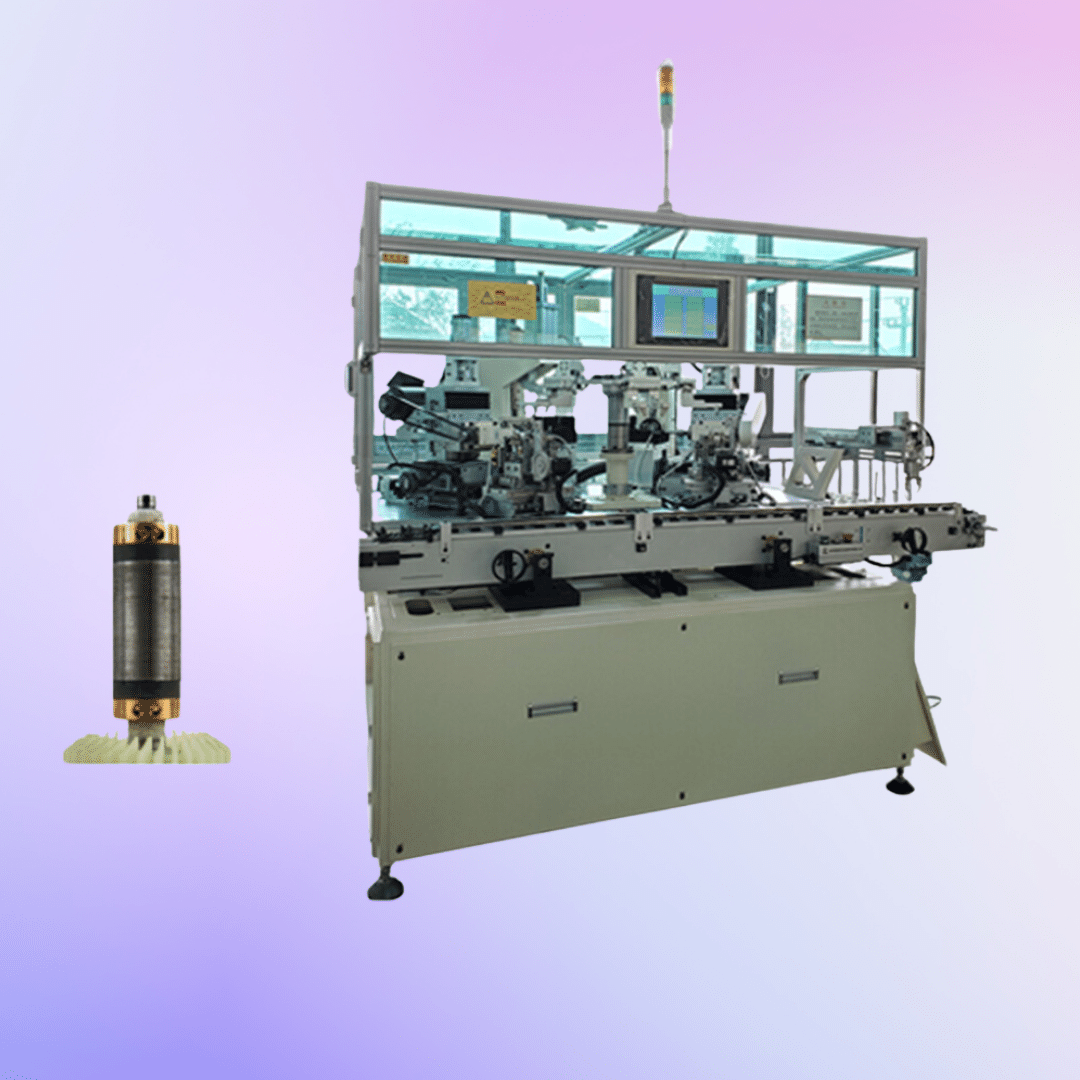

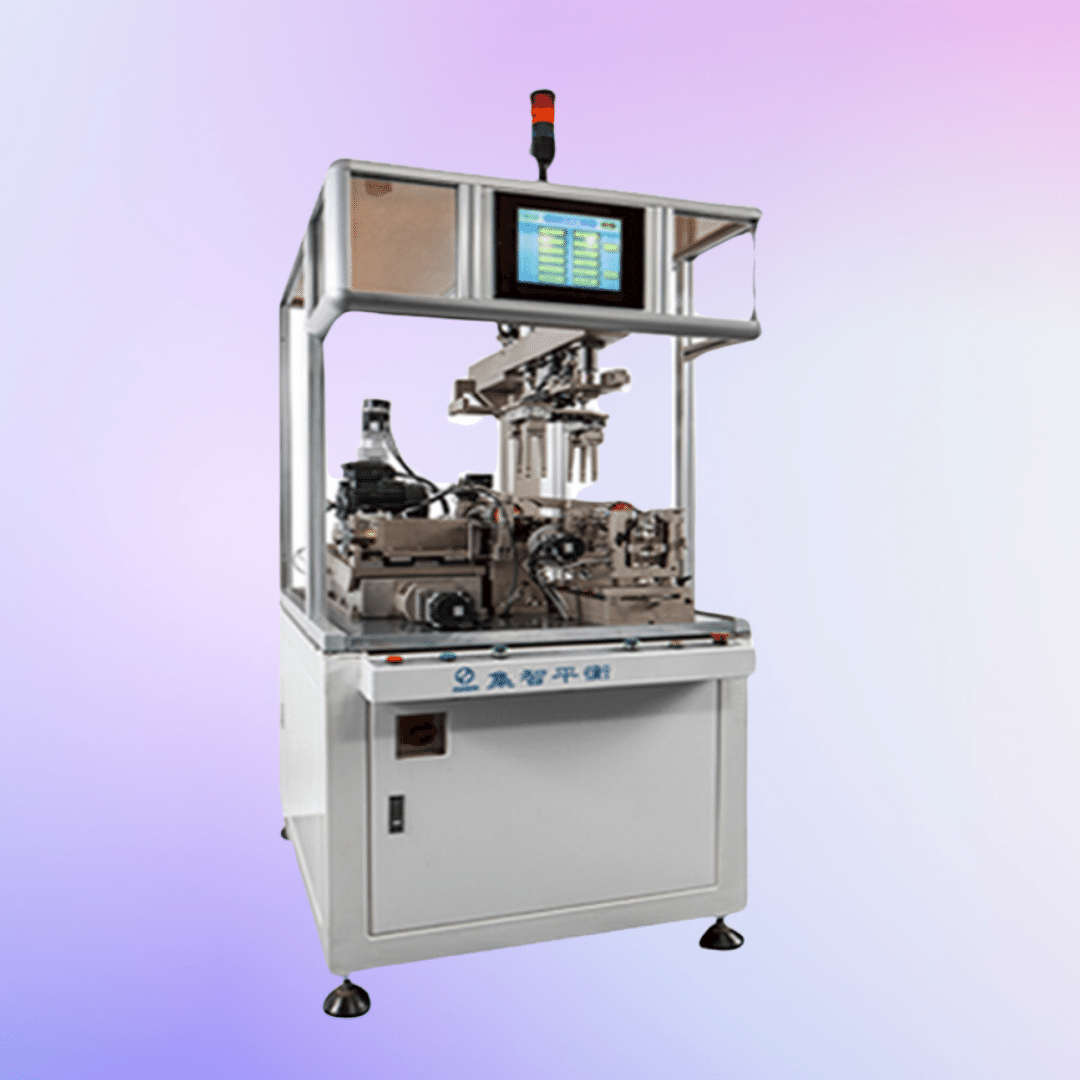

It is suitable correction of various miniature winding rotors such as DC small motors, electric tools, small household appliances, and automobile starter motors; it is compatible with some brushless motor rotor dynamic balance corrections.

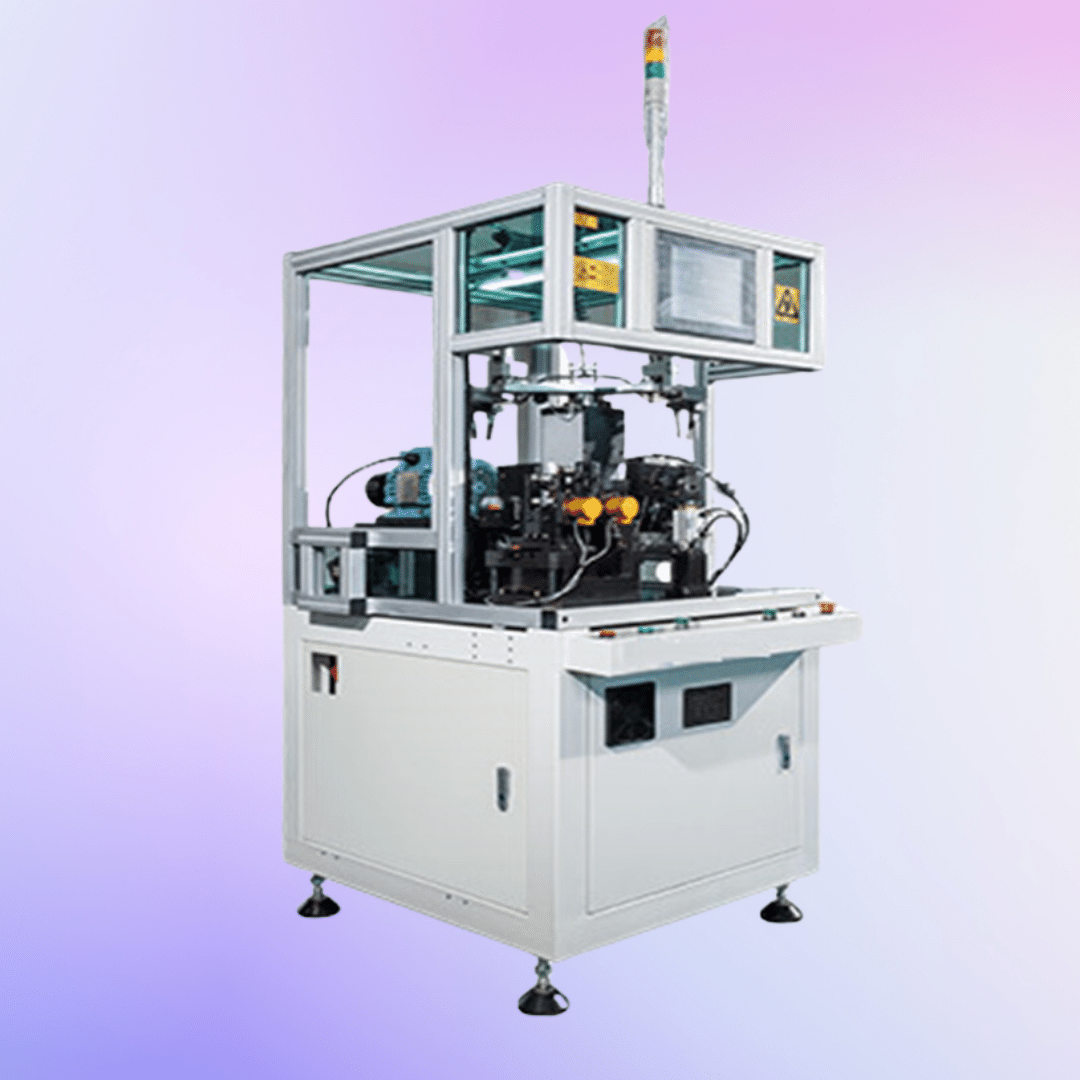

Dynamic balancing machine is mainly suitable for dynamic balance correction of new energy vehicle motor rotors. It has high efficiency and is suitable for mass production; it has strong compatibility, fast model change, and wide application range.

It can be equipped with a separate automatic assembly line, or it can be connected with a fully automatic rotor production line, and have wide application range, fast type change, suitable for quick change of small batches and multiple varieties.

Dynamic balancing machine is mainly suitable for dynamic balance correction of new energy vehicle motor rotors. It can be connected with the manipulator for automatic loading and unloading, and the operation is simple.

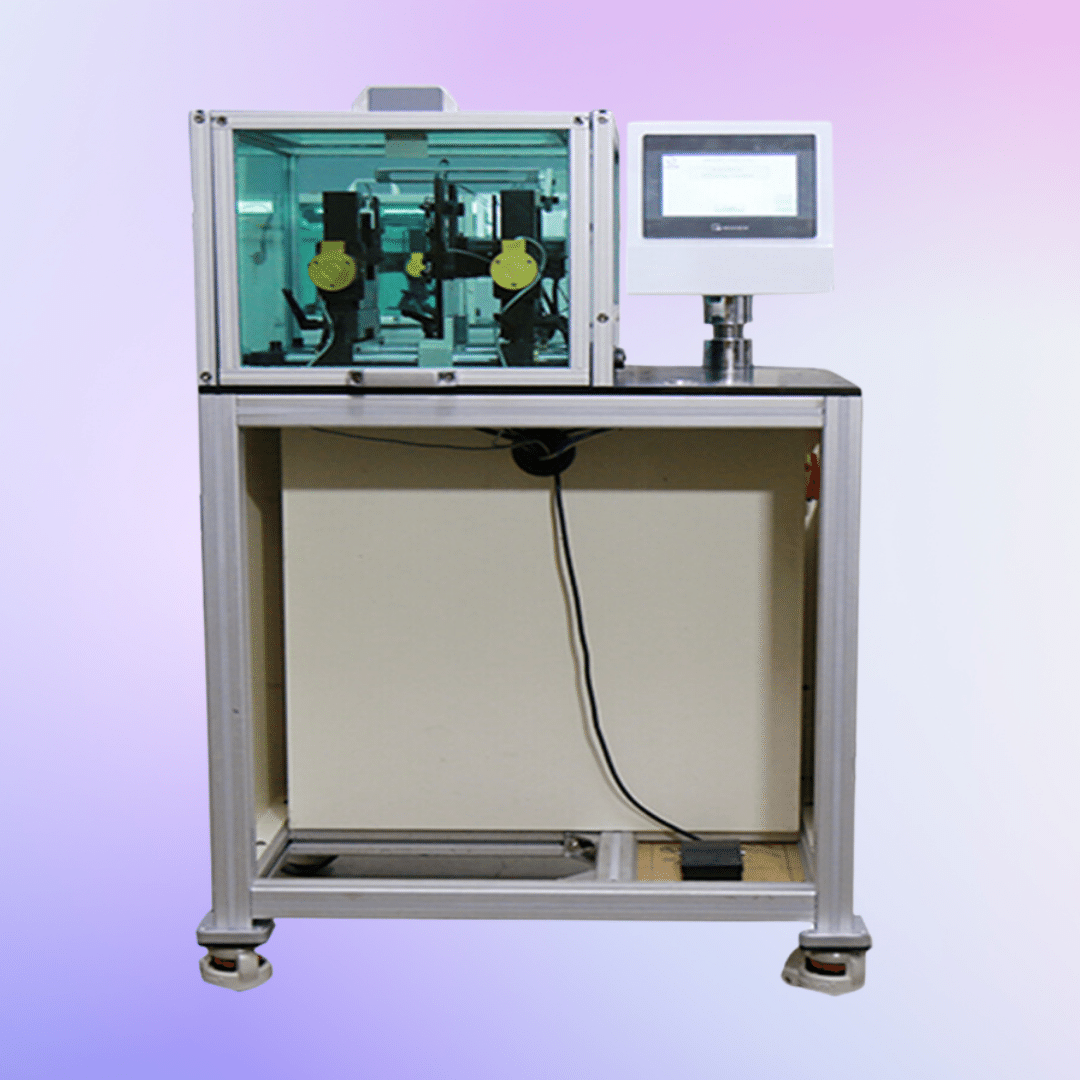

Dynamic balance testing machine is suitable for the correction of various workpieces such as motor rotors with a rotor radius range of 3.5 kg, steel sheet stack thickness of 10-70mm, and rotor diameters of Ф20-100mm.

It can be equipped with a separate automatic assembly line, or it can be connected with a fully automatic rotor and Compatible with magnetic rotor dynamic balance correction.

It is suitable for the dynamic balance correction of various workpieces such as motor rotors with a rotor radius range of 3.5 kg, steel sheet stack thickness of 10-70mm, and rotor diameters of Ф20-100mm.

It is suitable for the dynamic balance correction of various workpieces such as motor rotors with a rotor radius range of 3.5 kg, steel sheet stack thickness of 10-70mm, and rotor diameters of Ф20-100mm.

Two-station automatic balancing machine is mainly suitable for dynamic balance correction of various small and small wound rotors such as electric tools, small household appliances, micro-motors, and automobile starter motors

Economical two-station automatic rotor dynamic balancing machine have Soft support high-precision measurement system, high accuracy of measurement data and good repeatability.

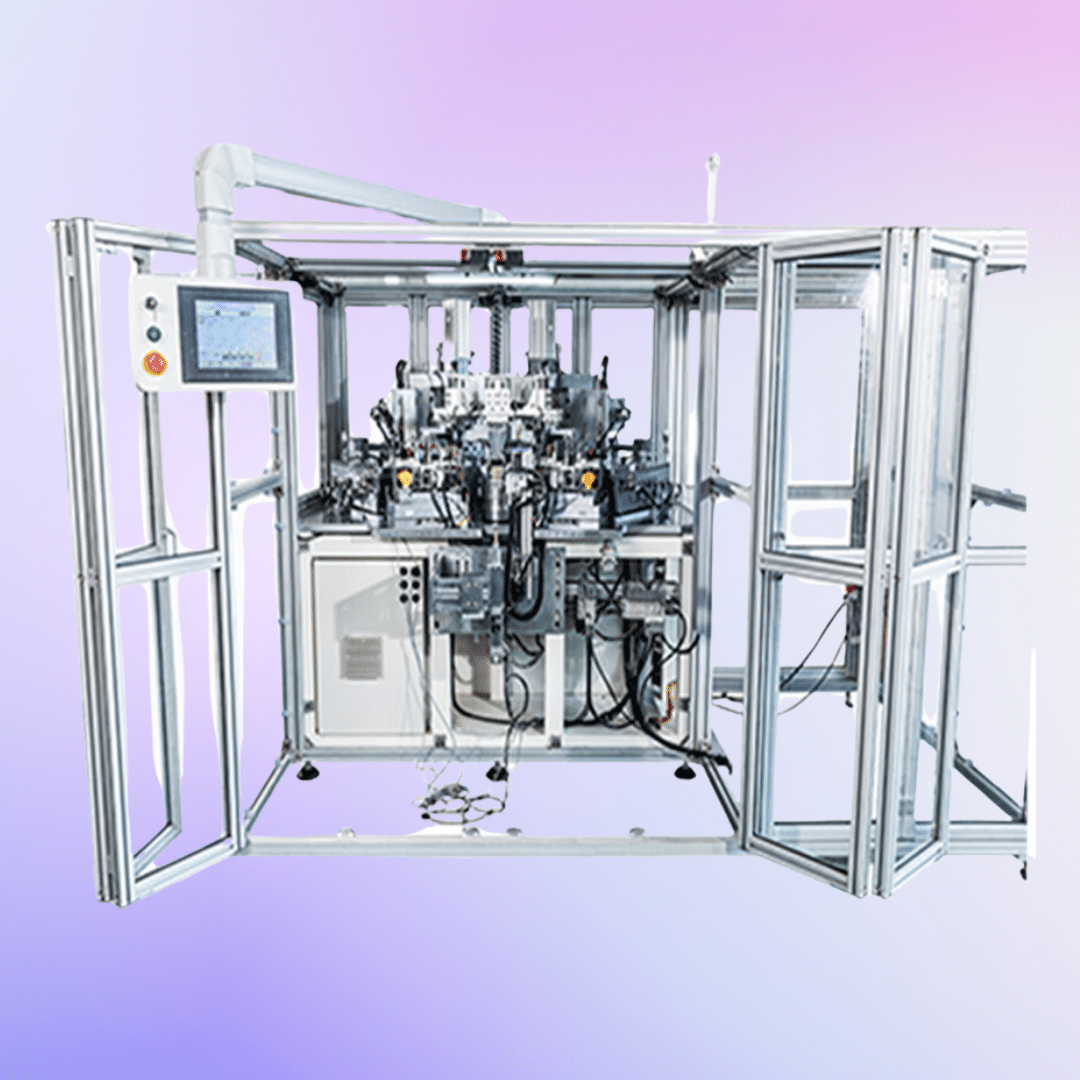

Economical five-station automatic rotor balancing machine can be operated as a stand-alone machine, can be connected to a fully automatic rotor production line.

It can be automatically balanced by a single machine, and can be connected to an automatic line for fully automatic production. It can be equipped with an MES system to achieve data traceability.

It can be equipped with a vision-based model recognition system, which can dynamically retrieve detection parameters according to the wheel hub model, and is suitable for mixed-line production.

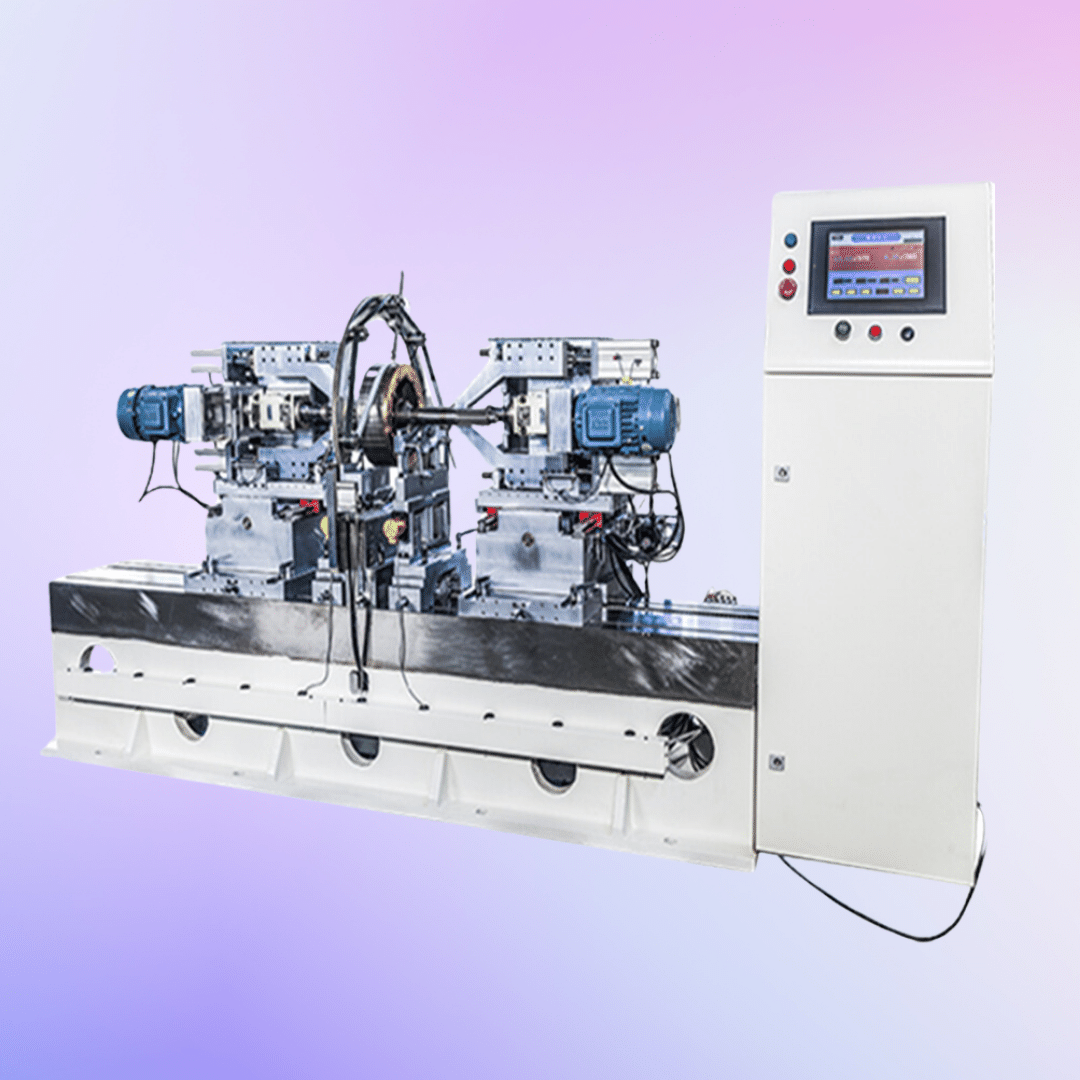

Generator rotor dynamic balancing machine is suitable for the dynamic balance correction of automobile generator rotors, and is compatible with the dynamic balance correction of brushless rotors such as induction motors.

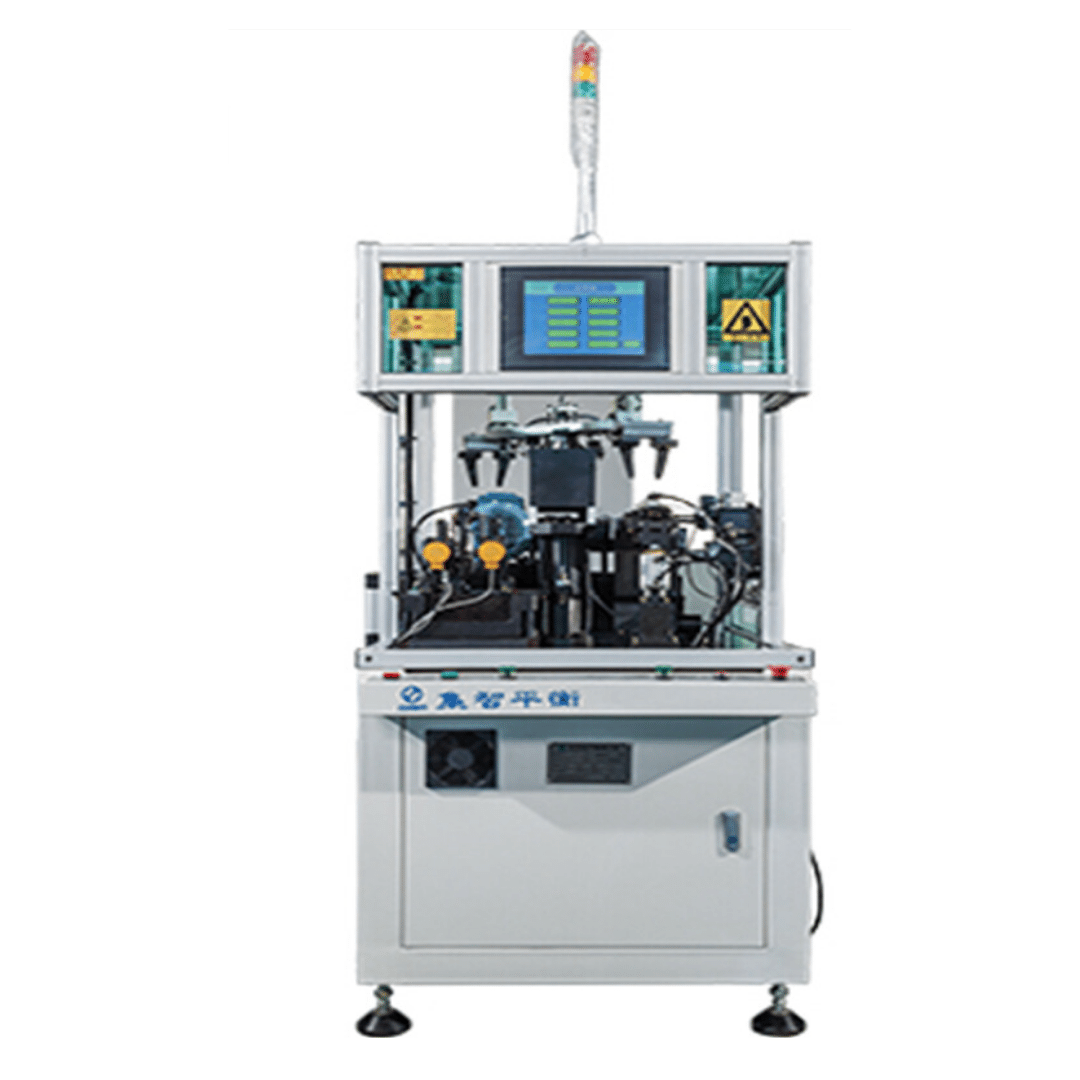

Motor rotor dynamic balancing machine is mainly suitable for dynamic balance correction of DC micro-wound rotors. Manual loading and unloading, sound and light prompts for qualified judgment, one person can operate two machines at the same time.

It is mainly suitable for dynamic balance correction of various types of wound rotors. The workpiece diameter is compatible with a wide range, and the type change is quick, fully automatic measurement and weight removal, simple training can be used for on-the-job

Dynamic balancing machine is mainly suitable for dynamic balance correction of new energy vehicle motor rotors. Hard support high-precision measurement system, high accuracy of measurement data and good repeatability.

It is suitable for the dynamic balance correction of 357 series micro-motor rotors with short stack height and high balance requirements, and is compatible with the dynamic balance correction of some brushless rotors with an outer diameter of 40mm or less.

It is suitable for the dynamic balance correction of automobile generator rotors. It can be equipped with a separate automatic assembly line, or it can be connected with a fully automatic rotor production line.

It can be equipped with a separate automatic assembly line, or it can be connected with a fully automatic rotor and easy maintenance.

The equipment has strong compatibility, the structure of the changeover is simple, the speed is fast, and it can be self driven.

It has automatic loading and unloading functions, and can classify qualified products and unqualified products and display can be set according to customer needs.

Equipped with a vision-based model recognition system, which can dynamically retrieve detection parameters according to the wheel hub model, and is suitable for mixed-line production.

Perfect comprehensive supporting ability, can provide flexible and diverse choices, and provide you with optimized product configuration.

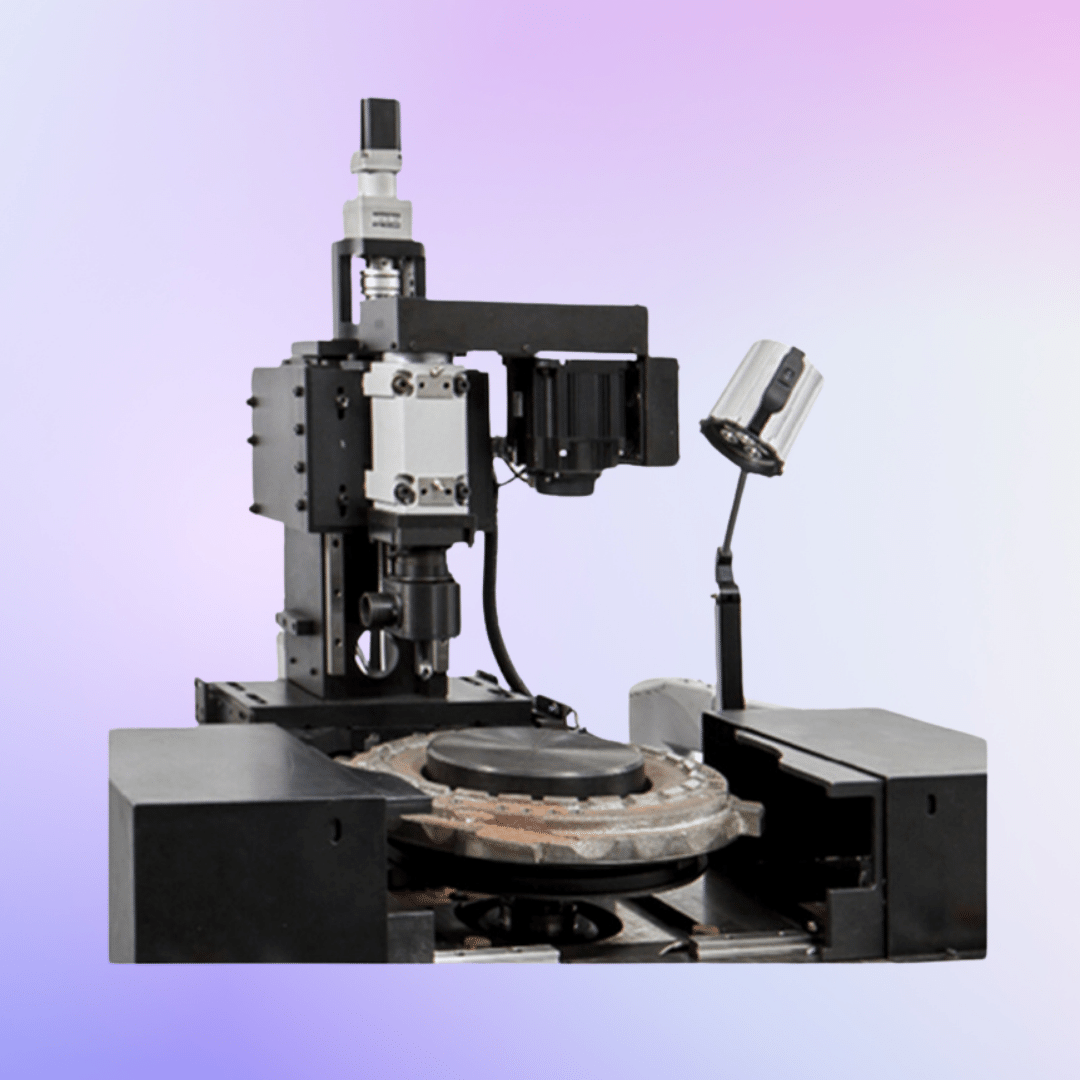

This series of equipment only needs to be adjusted according to the radius of the two correction surfaces of the rotor before starting, and it can correctly display the unbalance and phase of the workpiece under one start.

It is fully automatic vertical double-sided dynamic balancing machine, simple training can be used for on-the-job operation.

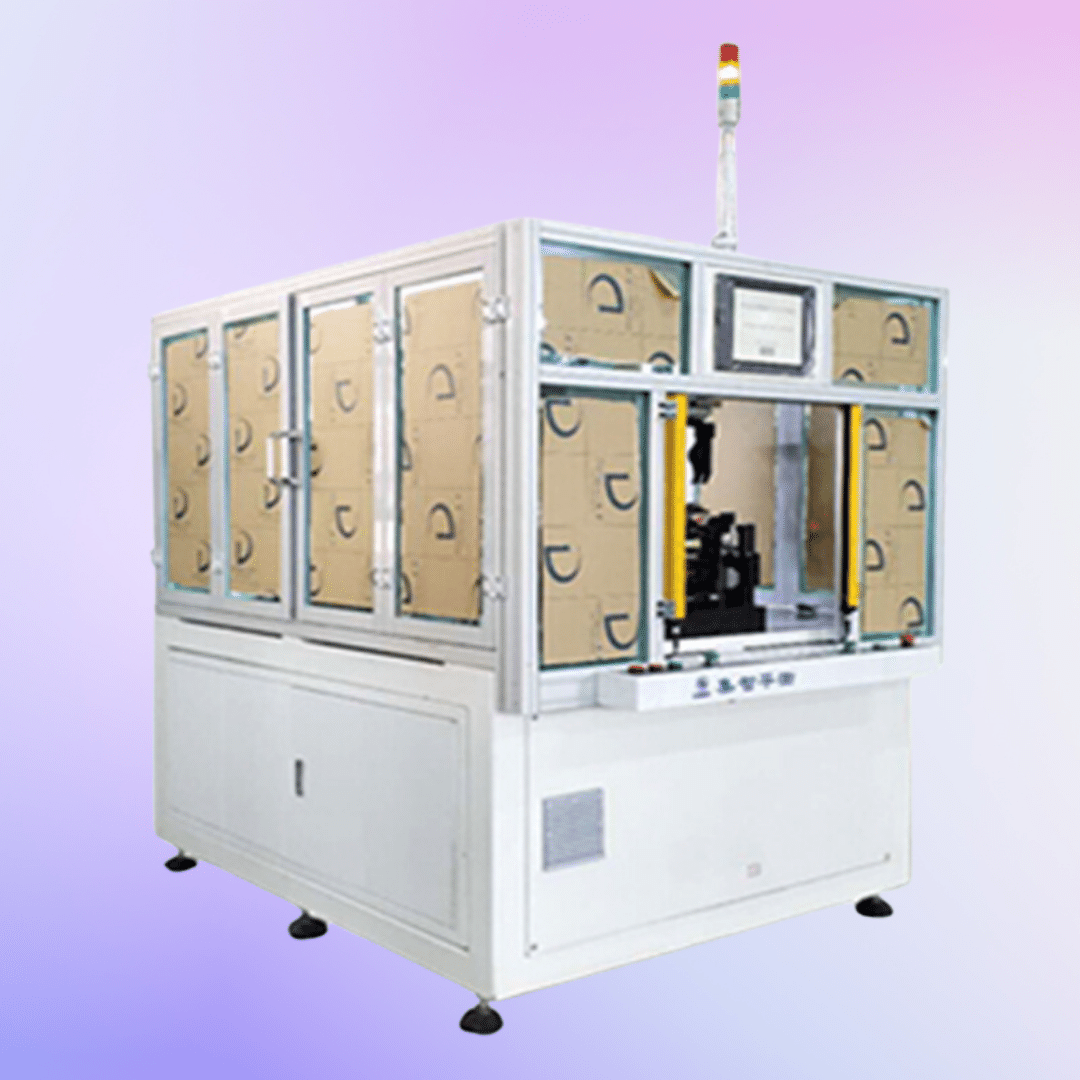

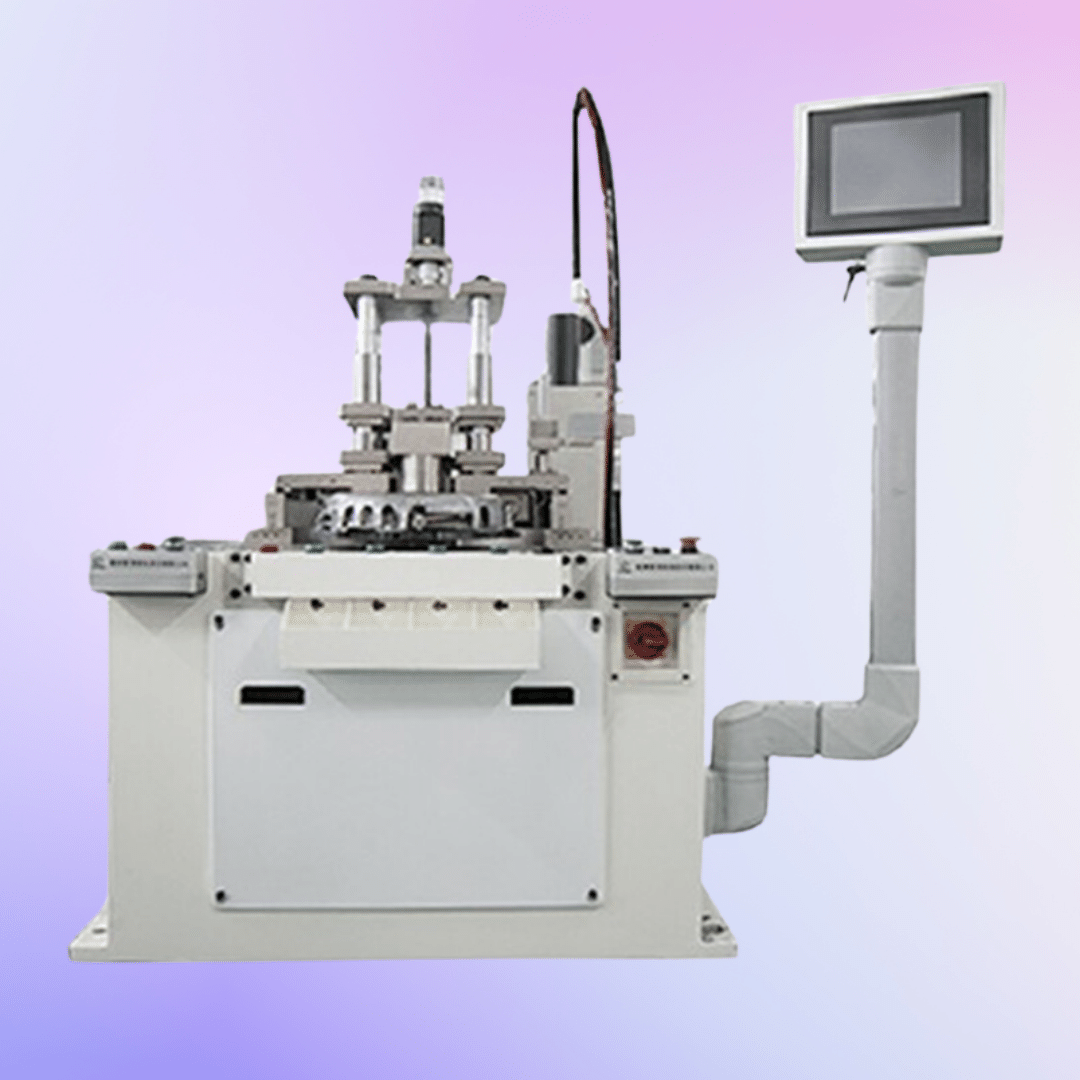

High efficiency, the working cycle of the equipment can reach 30 seconds, high processing accuracy, good stability, and convenient changeover.

It can be operated as a stand-alone machine, can be connected to a fully automatic rotor production line and high efficiency, suitable for mass production.

The equipment has strong compatibility, the structure of the changeover is simple, the speed is fast, and it can be operated.

It can be automatically balanced by a single machine, and can be connected to an automatic line for fully automatic production. It can be equipped with an MES system to achieve data traceability.

Strict and complete quality system, perfect and complete process, testing means and configuration of various gold processing equipment ensure the quality of products.

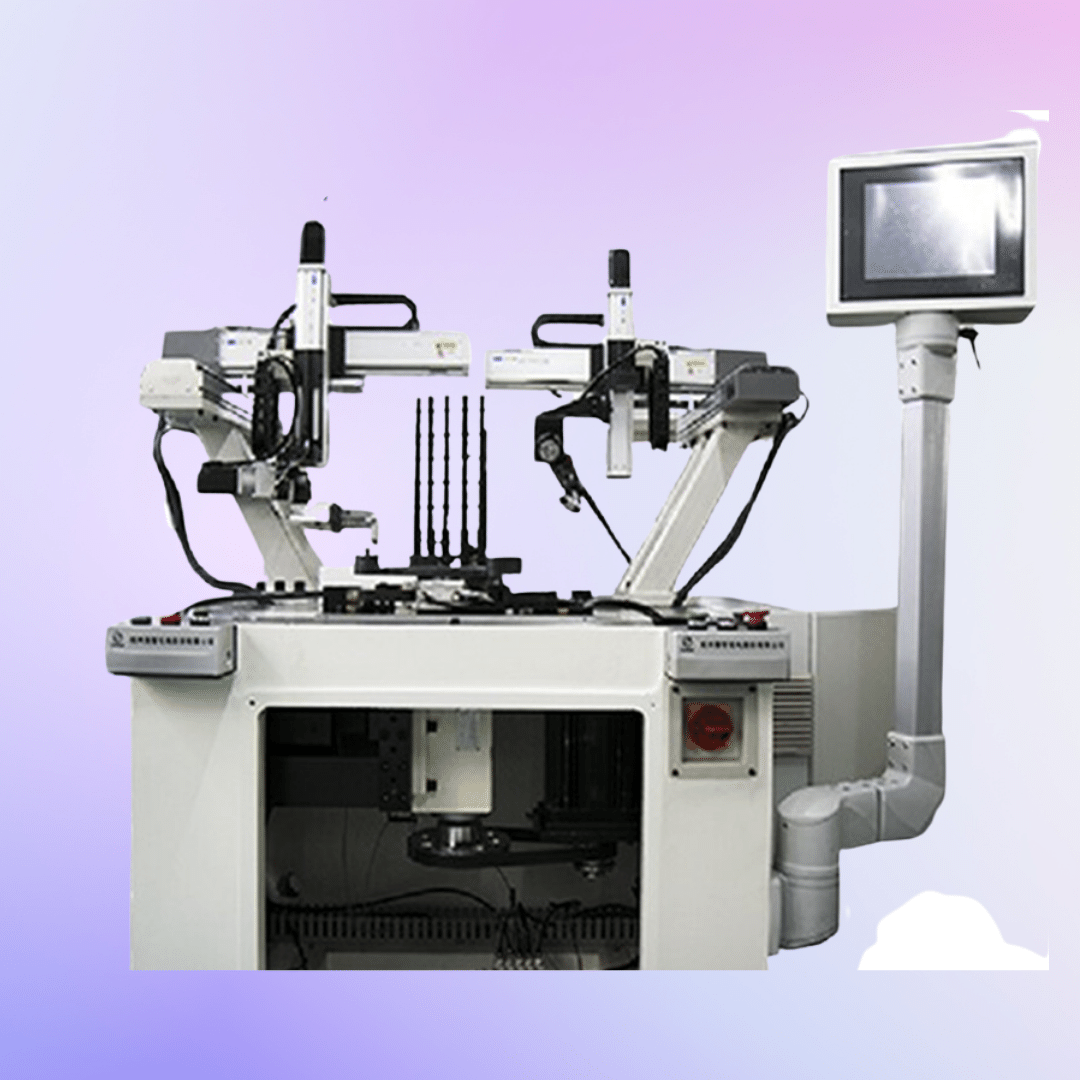

Equipped with 2 sets of 4-axis robotic arms, the automatic clamping of the welding block and the automatic welding of the welding torch are realized.

This machine adopts measurement, riveting weighting and re-inspection to be carried out at the same station to reduce labor intensity and improve efficiency.

It can be operated as a stand-alone machine and the assembly line automatically loads and unloads materials, and the rotor is automatically separated.

Quick change of tooling and fixtures, parameterized adjustment and changeover, automatic tool setting, and improved changeover efficiency.

Strict and complete quality system, perfect and complete process, testing means and configuration of various gold processing equipment ensure the quality of products.

Simple, the operator can operate after a short period of training and Photoelectric safety protection, automatic alarm and shutdown in case of failure.

High efficiency, the working cycle of the equipment can reach 30 seconds, high processing accuracy, good stability, and convenient changeover.

Photoelectric safety protection, automatic alarm and shutdown in case of failure. Fully independent intellectual property rights, special products can support highly customized solutions.

Fully automatic measurement and weight removal, simple training can be used for on-the-job operation. Wide application range, strong compatibility, suitable for quick change of small batches and multiple varieties.

The workpiece diameter is compatible with a wide range, and the type change is quick, suitable for manual loading and unloading, sound and light prompts for qualified judgment.

It is suitable for dynamic balance correction of automobile generator rotors with an outer diameter of 80mm or more. It can be operated as a stand-alone machine, can be connected to a fully automatic rotor production line.

The HW310 new generation dedicated electrical measurement system that this machine is equipped with is based on the PLC platform, with stable measurement, complete functions, touch screen operation, and powerful man-machine dialogue.

Simple, the operator can operate the photoelectric safety protection after a short period of training, and it will automatically alarm and stop if there is a failure.